Application of bubble cap trays in distillation towers

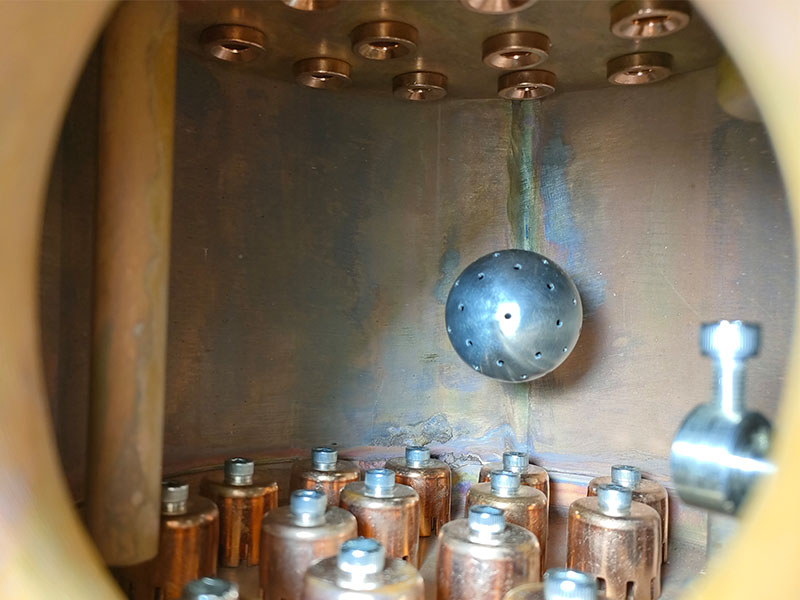

The bubble cap tray is an integral part of the distillation column and is designed to increase the efficiency of the distillation column. Located within the column, these trays are precisely designed to facilitate the separation of liquid components by allowing vapor to rise through the bubble cap, creating a dynamic interaction that optimizes the distillation process.

How the bubble cap tray works:

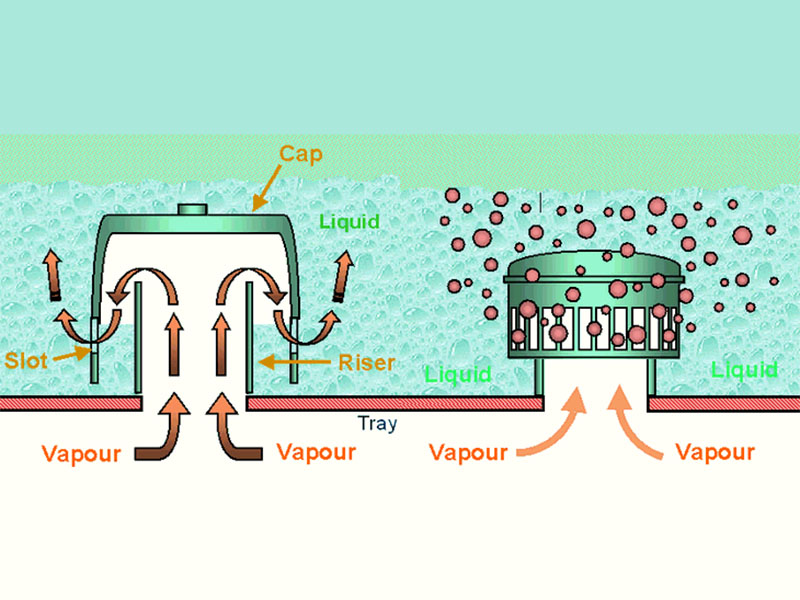

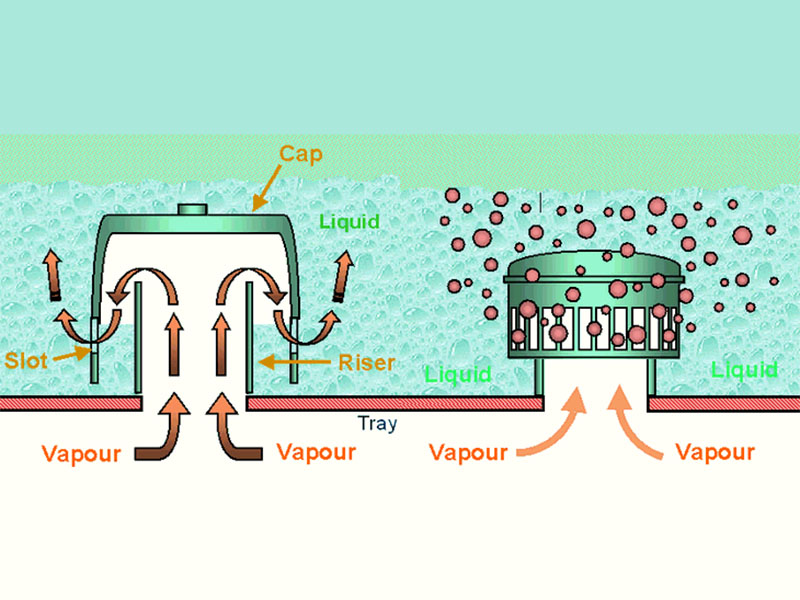

1. Vapor-liquid interaction:

As the vapor rises through the column, it encounters a bubble cap on each tray. The bubble action created by these caps promotes increased surface contact between the vapor and liquid, thereby enhancing mass transfer.

2. Separation efficiency:

Bubble cap trays effectively separate components with different boiling points, ensuring a precise and controlled distillation process.

The bubbling action minimizes back-mixing, resulting in clear separation of the components.

Advantages of bubble cap tray:

1. Improve heat transfer:

Continuous bubbling enhances heat transfer, resulting in more efficient separation at lower temperatures.

2. Reduce channeling:

Bubble cap trays minimize channeling and ensure even vapor distribution within the tower.

3. Specific process customization:

Manufacturers offer a variety of designs, allowing users to select a tray that suits their specific distillation requirements.

In the field of distillation, the right equipment can make all the difference. Bubble cap trays play a vital role in achieving optimal separations with their innovative design and ability to increase efficiency. By understanding the capabilities of bubble cap trays and considering key factors when selecting a manufacturer, engineers can optimize the design and operation of distillation columns for a variety of industrial applications.