Control your heat intensity and steam flow rate during distillation

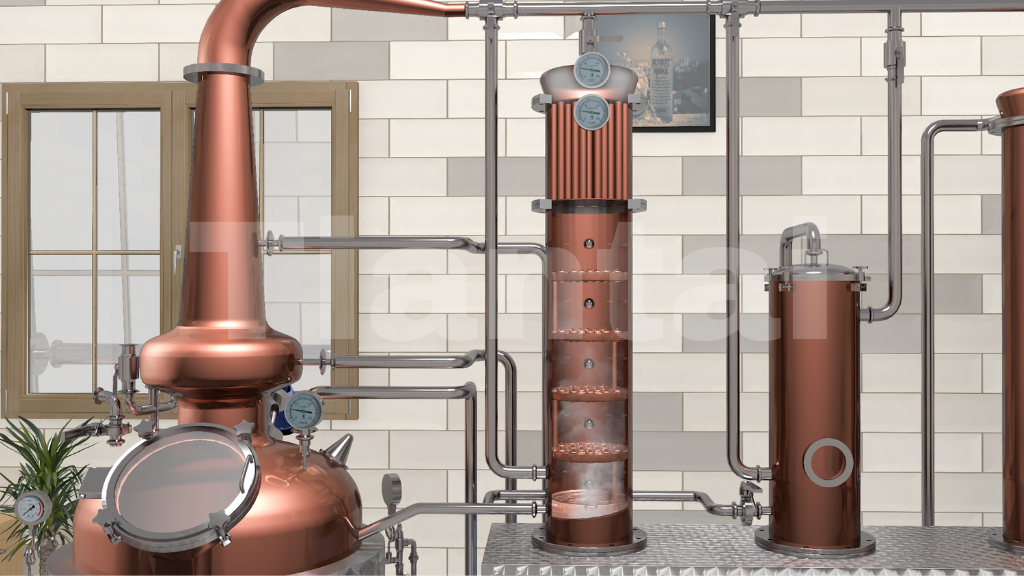

As the core link in the spirit-making process, distillation aims to separate the alcohol and other volatile substances in the fermented liquor through heating and condensation, and then form the spirits we are familiar with. In this process, the adjustment of heat intensity and steam flow rates are directly related to the flavor, taste and quality of your spirits.

Heat Intensity:

- Intense Heat: Increases volume but lowers alcohol concentration and introduces more impurities and flavors.

- Soft Heat: Decreases volume but results in higher alcohol purity with fewer impurities and flavors.

Remember, distillation doesn’t create alcohol but extracts it from the mixture, varying its concentration based on the process.

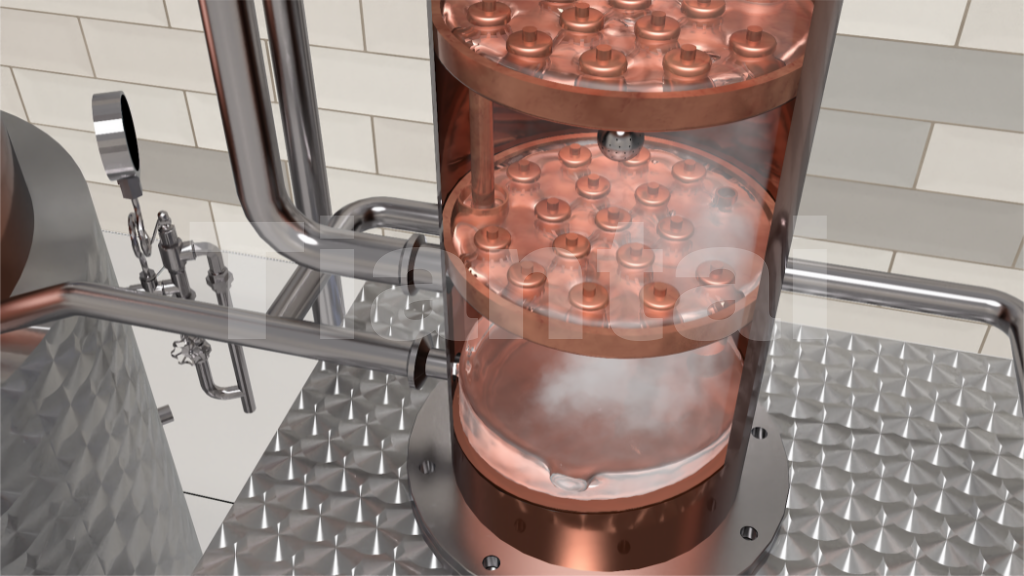

Flow Rate:

- Faster Flow: Running your still with a steady, thin stream yields more volume at a lower ABV with richer flavors, producing a smooth finish.

- Slower Flow: Maximizes separation and reflux, resulting in less volume but higher ABV with fewer impurities. However, this often produces a hotter taste.

Adjusting the flow rate is key. Running it too fast can cause heads and tails to mix with the middle cut, which is undesirable in cuts run but acceptable in a stripping run.

Taking the above into account, it is up to you to decide whether you would like to maintain a certain balance at a lower flow rate and soft heating to preserve the desired sweetness and grain flavors, or a faster flow rate and intensive heating to achieve a more pure profile.