Crafting Exceptional Distillates: How Product Apple Brandy

Exceptional distillates are crafted by utilizing top-quality fruits and raw materials, cultivated organically by local producers, and harvested at their peak ripeness. For many distilleries, if certain ingredients for brandies cannot be optimally grown in their region, they are sourced from specialized regions renowned for those items.

Emphasizing the utmost quality is the primary focus, so all raw materials are exclusively processed on-site. This meticulous approach ensures the exclusion of undesirable off-flavors; for instance, any flawed plums are meticulously removed. A skilled distiller comprehends the distinct characteristics of each fruit or raw material, and, at day’s end, is acquainted with every piece of fruit personally.

Adapting to changing climates, the quality of fruit varies yearly. As a vintage distillery, decisions are made annually on which fruits and in what quantities will be utilized – working in harmony with nature. Some years may yield limited quantities of rare fruits, requiring enthusiasts to act swiftly to secure these unique offerings.

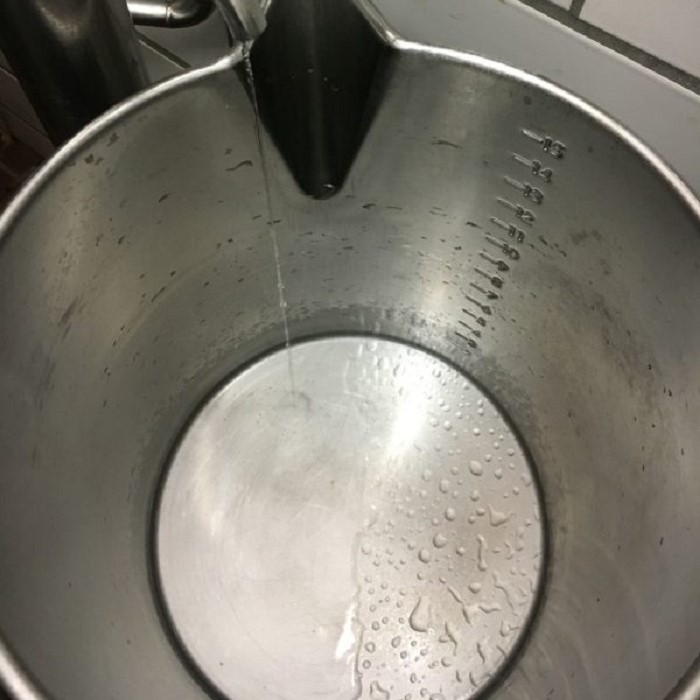

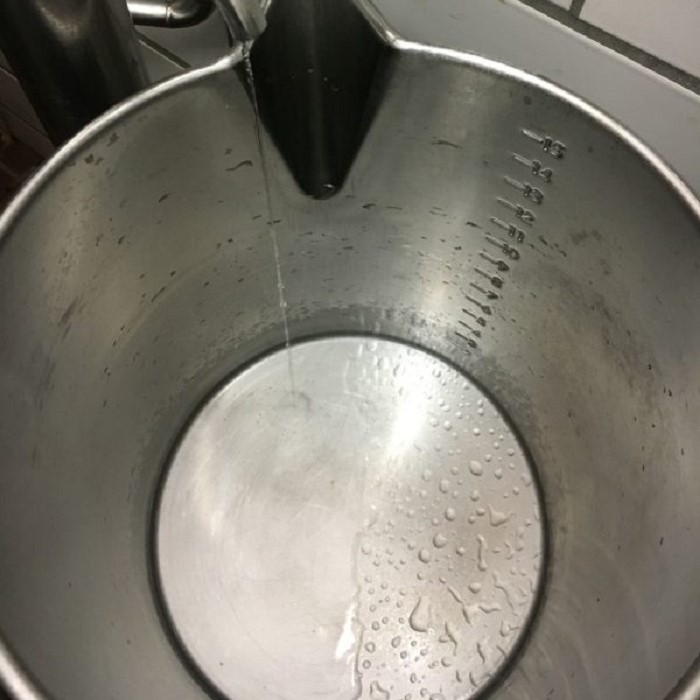

In addition to hard work, meticulous care, particularly in hygiene, is paramount. The tanks undergo thorough cleaning to ensure that only the intended elements reside within, as even a trace of residual fruit could compromise the entire batch.

Now, turning our attention back to apples… The foundation for excellent quality lies in top-notch raw materials:

70% of apples are handpicked from the tree.

20% are windfalls collected within 24 hours.

10% consists of slightly damaged apples, with any imperfections carefully removed.

The delivered apples undergo thorough washing and cleaning. Determining the sugar content of the apples, measured as the Brix degree, is crucial for brandy production.

Different apples from various sources are sampled to calculate an average sugar content, considering factors such as sunlight exposure. The higher the sugar content, the more alcohol is generated during fermentation.

Moving on to the process of making brandy, the apples, once cleaned and measured, are finely chopped into 3mm pieces using a stainless steel milling machine. Time is of the essence to prevent oxidation. Sulfuric acid is added to the mash to prevent acetic acid bacteria, and the mixture is carefully sealed in cleaned barrels.

In the laboratory, yeast is prepared and added to stimulate fermentation. After approximately 2 weeks, the fermented wash is ready for distillation.

The distillation process involves heating the apple mash in a copper still, allowing the alcohol to evaporate, and concentrating aroma components. The distilled spirit is separated into three fractions: the head (volatile substances), the heart (tasteful and reflective of fruit character), and the tail (fusel oils).

The resulting apple brandy, with an average alcohol content of approximately 80%, undergoes a resting period to develop new aromatic substances. Storage vessels include wooden barrels, glass carboys, or stainless steel containers for up to four years.

Post-distillation, the undiluted brandy is meticulously adjusted to a drinkable alcohol content between 37.5% and 40%. Filtration, especially at low temperatures, and adding flavors or sugar varies by country.

Distillation is not merely a technical process; it demands experience, passion, skill, and considerable patience. The realization of the effort involved makes each undiluted liter of distillate reinforce the dedication and craftsmanship behind this high-quality luxury product.