Distillation Column Internals

Distillation Column the internal devices may be grouped into two general categories: Tray-type and Packing-type.In this blog, we have discussed tray-type internals. Three types of cross-flow trays are the most commonly used type of vapour and liquid contactors in the distillation columns. In a cross-flow type, the liquid flows across the tray, and the vapours rise up through the plate. The flowing liquid is transferred from the plate to the plate through downcomers. A certain level of the liquid is retained on the plate by an outlet weir.

1. Bubble Cap Trays

A bubble cap tray has riser or chimney fitted over each hole, and a cap that covers the riser. The cap is mounted so that there is a space between riser and cap to allow the passage of vapour. Vapour rises through the chimney and is directed downward by the cap, finally discharging through slots in the cap, and finally bubbling through the liquid on the tray.

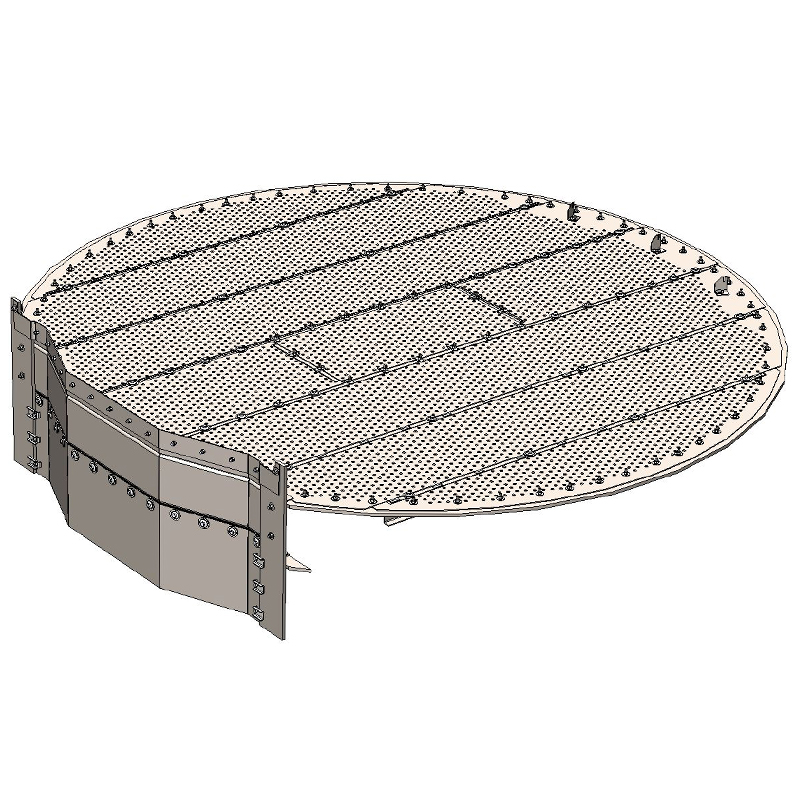

2. Sieve Tray

The sieve plate is the simplest type of cross-flow plate. The tray contains round small holes, and perforations (⅛ to 1-in.) punched on the tray deck. Vapour rises through the small perforations on the tray floor and bubbles through the liquid in a fairly uniform manner. The liquid then flows across the tray floor over the weir, through the downcomer to the tray below.

The holes on the tray give a multi-orifice effect. The vapour velocity keeps the liquid from flowing down through the holes. Liquid flow is transported down the tower by downcomers and weirs to the overflow device on the side of the plate.

In sieve plates, the liquid is prevented from flowing through the sieve tray perforations by the upward-flowing action of the gas; thus, when the gas flow is low, it is possible for some or all of the liquid to drain through the perforations and in effect bypass portions of the contacting zone. This phenomenon is called weeping.

The function of a tray is to mix the vapour and liquid together to form a foam. Vapours bubble up through the tray sieve holes, where the vapour comes into intimate contact with the liquid. The fluid on the tray is a mixture of vapour and liquid in the form of froth or foam. This foam should separate back into a vapour and a liquid on the tray and in the downcomer. If the foam cannot drain quickly from a downcomer onto the tray below, then the foamy liquid will back up onto the tray above. This is called Flooding.

3. Valve Trays

The openings in valve trays are covered with liftable caps that adjust themselves according to the vapour flow. Tray valves or caps close off at a low vapour rate, thus stopping the liquid from moving down from the tray. As the vapour rate increases, the valve lifts, and the open area for vapour flow also increase.

In valve trays the openings may be varied by the vapour flow, so the trays can operate over a wide range of flow rates with high separation efficiency and large flexibility. Because of their flexibility and reasonable price, valve trays are tending to replace bubble-cap trays.

The valve plate is designed to minimize this drainage, or “weeping,” since the valve tends to close as the gas flow becomes lower, the total orifice area varying to maintain a dynamic-pressure balance across the plate.

The valves on the trays can be fixed or moving. The fixed valves are permanently open while the moving valves adjust themselves according to the vapours flowing up through the tray holes as discussed.

The above is an introduction to the internal structure of distillation. If you want to know more information, please contact Tiantai.