Distillation Equipment

Tiantai, best distillation equipment manufacturer

Made in China

Great price

Professional service

Manufacturing and installation

Worldwide dealer network

Short delivery time

Pot Stills / Column Stills / Hybrid Stills

At Tiantai, we specialize in crafting premium copper stills to meet various distillation needs, from home distillation to craft breweries and professional distilleries. Our distillation units can be customized to do it all, whether you’re looking for a pot still, column still, or hybrid still.

Based on a typical pot still, we can customize it with column stills, gin baskets, doublers, and other devices to meet your distillation needs. Additionally, the shape of the helmet and the slope of the lyne arm can be tailored to suit the characteristics and distillation methods of desired spirits.

Request A Quote

■ Four-layer construction of pot, with an interior composed of copper

■ Tailored Shape Of Helme: Onions, pears, lanterns, spheres helmet shapes

■ Tailored Slope Of The Lyne Arm: The slope of the lyne arm can be positive, neutral or negative

■ Every 4 trays as a plate group, can be added as needed.

■ To enhance your distilling both on-grain and clear spirits/lautered wort, we will install a complete 304 stainless steel motorized agitator. The agitators not only improve heating rates but also prevent the scorching of grains on the inner surfaces of the still.

■ Gin basket is always an optiona. The addition of a gin basket allows for the infusion of botanical flavours into the distillate vapour. The gin basket will be fitted with a bypass valve that allows steam to bypass the gin basket and go directly to the next step when the botanical flavors are not desired.

■ As your requirement, spirit tails from previous batches, the current wash, or water can be added in the doubler. Its interior is made entirely of copper and functions as a small pot still. This configuration gives your alcohol a distinctive flavor profile after the column distillation process.

■ Bypass valves are installed on all connections to control which section of the still your spirit vapors travel through, meaning you can achieve various desired distillation characteristics through different process paths.

■ Our priority is safety and effective heating. Based on your distiller size, we recommend different methods such as electric heating, steam jacket, and water/oil bath covered in stainless steel and insulation.

1st Stripping

Pot

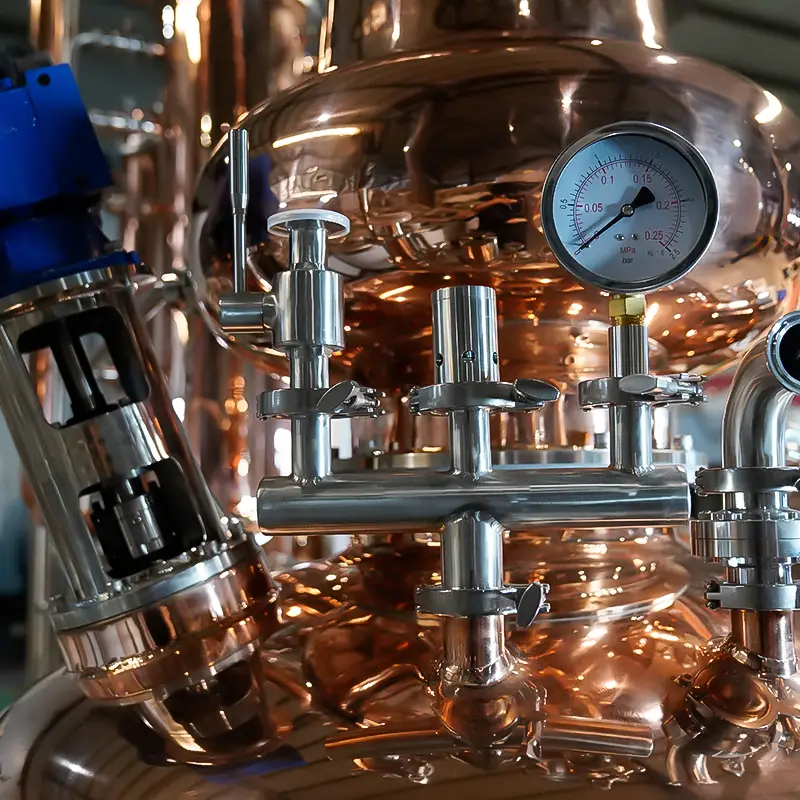

The pot boasts a sturdy four-layer construction, with an interior composed of copper. Inside, there’s insulation using either rock wool or high-density polyurethane, effectively maintaining ideal temperature control.

Safety valves are mounted on the helmet of the pots. Once the steam pressure exceeds the rated standard, the valves will automatically open to release the pressure.

2nd Reflux

Column

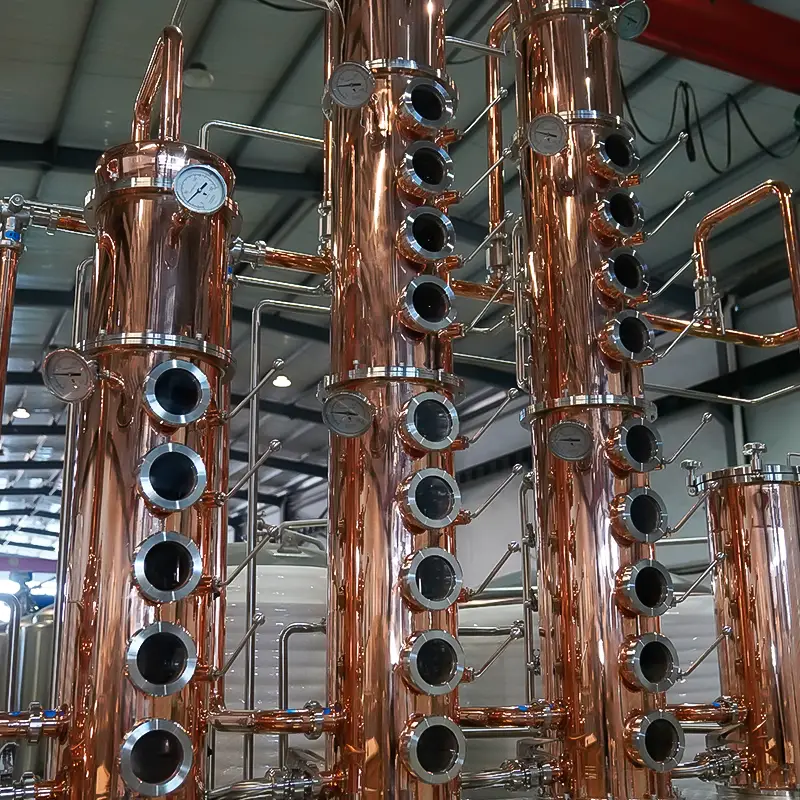

Whether a single-column still or a multi-column rectification still, our continuous distillation systems are individually tailored and meticulously hand-manufactured.

Each tray contributes to the separation process. The purity of the end spirits is influenced by the number of trays or the length of the column. If a highly pure product is desired, a greater number of trays or a longer column is recommended. There’s no standard length, it will be tailored to each specific situation.

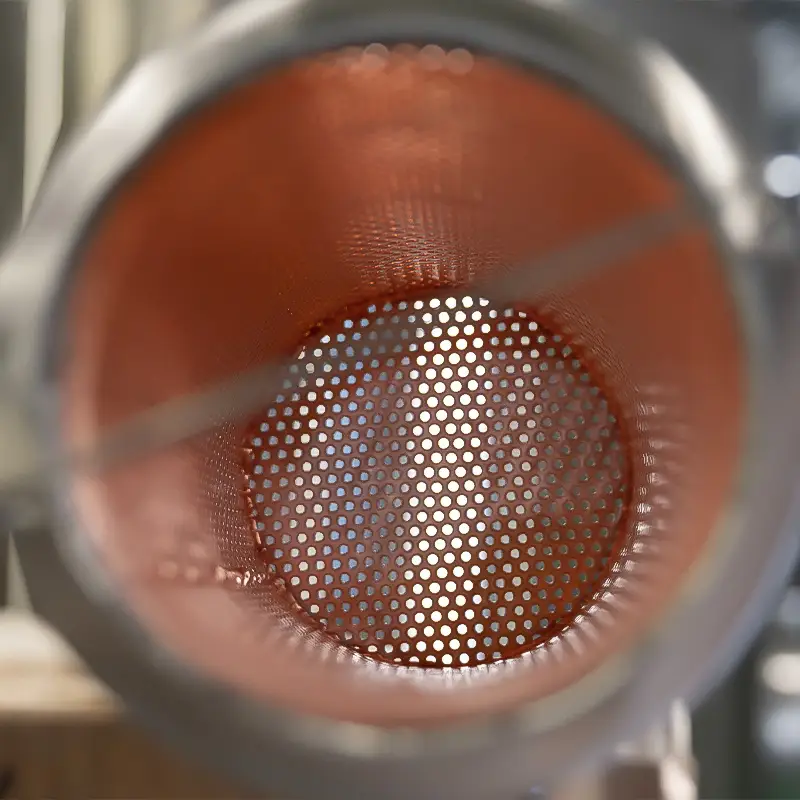

Our engineering team will determine the ideal diameter of the punched holes and the column based on the throughput you require. This customization ensures that the column matches your specific needs.

3nd Condensation

Condenser

Every pot still is equipped with a shell and tube condenser with stainless steel tubing, which can efficiently condense ethanol vapors into liquefied alcohol at 20℃. Condensers with copper tubing are also available. This final copper exposure results in a cleaner young spirit with fewer flavor-affecting sulfur compounds.

4nd Collection

Spirit Safe

A spirit safe is a three-chamber receiver tank for the collection of distillate. We utilize 304 stainless steel, ensuring it meets food-grade standards both inside and out. As the different condensed vapors come off the still throughout the batch, the distiller will route them into each of the three chambers.

Distillers need to distinguish between heads, hearts, and tails. The condensed liquid is subsequently drained through the parrot’s beak and heads, hearts, and tails are collected in three distinct tanks at the appropriate intervals. For smaller batches, the receiver tanks can be placed below the condenser, whereas for larger output, they can be designed outside the distiller and connected via piping.

We are knowledgeable in the techniques and equipment needed to distill any spirit, whether whiskey, vodka or gin, etc., Tiantai team has designed, expanded, and built new distilleries worldwide.