Selecting the Optimal Heating Method for Commercial Distilleries

Choosing the right heating method is a crucial decision in establishing a commercial distillery, as it profoundly impacts the quality and efficiency of the distillation process. With various options available, selecting the most suitable heating technology requires careful consideration of several factors. In this comprehensive guide, we delve into the key considerations and compare two primary heating methods: steam heating and direct fire heating.

Steam Heating

Steam heating is widely regarded as a reliable and efficient option for distilleries. It offers precise temperature control and scalability, making it suitable for operations of any size. While steam heating entails a higher initial investment due to the complexity of installation and setup, it provides superior heating control and is cost-effective in the long run.

When opting for steam heating, the choice of fuel for generating steam plays a crucial role. Natural gas is often preferred for its affordability and convenience, but alternatives such as propane or fuel oil can be viable depending on availability and local regulations.

Direct Fire Heating

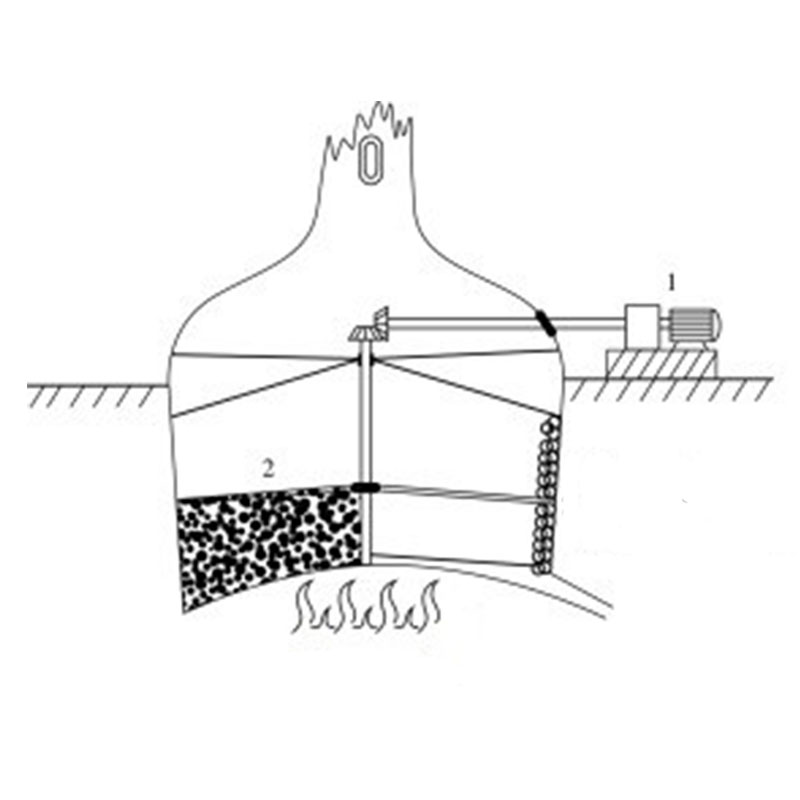

Direct fire heating involves exposing the distillation vessel to an open flame, imparting unique flavor characteristics to the final product. However, it is essential to note that some jurisdictions prohibit open flames in alcohol production facilities, necessitating compliance with local building codes.

Despite potential flavor benefits, direct fire heating requires meticulous design considerations to ensure safety and efficiency. Factors such as enclosing the fire within a sealed furnace and assessing the availability of low-grade fuels are paramount when implementing this method.

The choice between steam heating and direct fire heating hinges on various factors, including facility requirements, budget constraints, and long-term operational considerations. Evaluating energy availability, installation costs, and maintenance requirements is essential for making an informed decision.

Ultimately, the optimal heating method for a commercial distillery depends on the specific needs and priorities of the operation. By carefully weighing the advantages and disadvantages of each option and considering factors such as flavor profile, production efficiency, and regulatory compliance, distillery owners can make a well-informed choice that aligns with their objectives.

In conclusion, selecting the right heating method is a critical step in establishing a successful commercial distillery. By thoroughly evaluating available options and considering key factors, distillery owners can ensure optimal performance, product quality, and long-term sustainability in their operations.