Steam Distillation – How to Extract Essential Oils

What are essential oils?

Essential oils are aromatic oils derived from different parts of plants, and with their unique benefits, application methods, and farming practices, it’s easy to get lost in the selection. Among the most popular essential oils, extracts of peppermint, lavender, chamomile and eucalyptus are popular. Essential oils are used for a variety of purposes, from improving our health to creating natural pesticides that don’t harm the environment. But before we can use essential oils for our own benefit, we must extract them from the plant material that contains them.

steam distillation

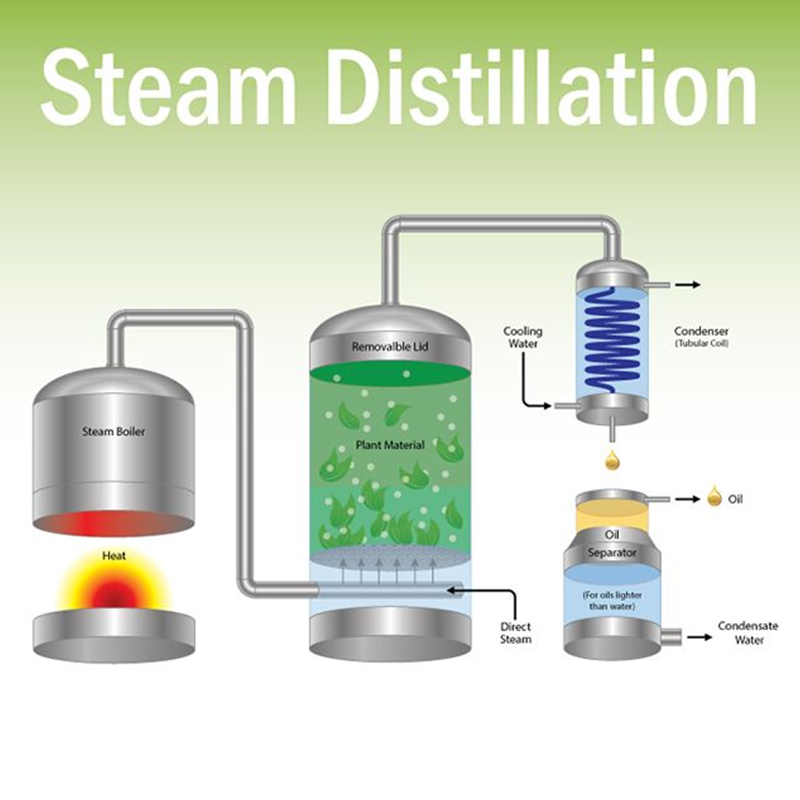

The extraction of essential oils can be done through a variety of methods. From cold pressing, maceration or hydro and steam distillation – different methods affect the retention properties of the oil. Steam distillation is often used by those seeking to preserve the plant in its purest form. Steam distillation of essential oils is the process of isolating essential oils by lowering their decomposition point. By reducing the boiling point of the organic compounds in the oil, thereby protecting the integrity of its delicate and complex chemical profile.

To separate essential oils by steam extraction (hydrodistillation), plant material is placed in a column above a boiler filled with water. The water is then boiled, and due to the high temperature of the steam, the essential oils are released from the oil glands (or glandular trichomes) in the plant tissue and enter the condenser along with the steam. The vapor mixture of water and oil is condensed by the cooling water and collected in the essential oil separator, where the oil and hydrosol (water mixed with water-soluble compounds in the plant material) naturally separate.

When using steam distillation, it is important to be aware of the heat source. The temperature of the system must be kept within a strict range; too low and the essential oils will not be distilled, too high and there is a risk of damaging the essential oils or collecting unwanted non-aromatic compounds. The temperature required for optimal steam distillation is usually between 140° F and 212° F (60° C and 100° C). One of the benefits of steam distillation is that the temperature can be continuously adjusted and precisely controlled to ensure that the system is always within the optimal temperature range. In addition to temperature, distillation time is also an important consideration. Each plant is unique and can take anywhere from a few hours to a few days to fully distill. Steam distillation of essential oils usually continues over a longer period of time until all the oil has been extracted from the plant.

Steam distillation of essential oils is highly technical and scalable and remains the industry’s most preferred and reliable method of extracting pure, organic and massively scalable essential oils. In terms of equipment, the still’s stainless steel tank should be a specialized tank designed specifically for the job. If you would like to know more about Tiantai’s distillation equipment or steam distillation, please feel free to contact us. Tiantai’s entire team is here to help you make sure you get the exact equipment you need to get the job done.