Technical Guide: How Distill Whisky with Tiantai Hybrid Still

Making whisky is a pretty exacting process with many steps to ensure the final product is up to scratch. If you want to distill top-quality whisky, it’s important to understand the ins and outs of this process. We’ve put together a handy guide below to show you the main steps in whisky distillation.

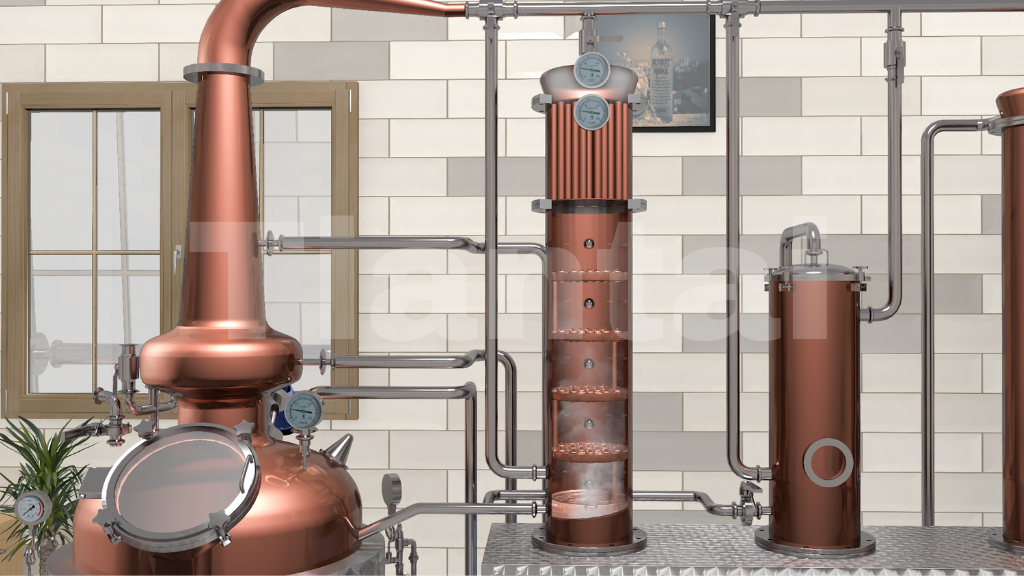

To begin the distillation process, start by introducing the fermented liquid containing alcohol into the pot. This liquid can be fermented from wort or grain-in mash. Next, start the steam supply of the still, typically set at a pressure of 1 to 1.2 bar. Just a heads-up: make sure the temperature doesn’t get above 100 degrees or you’ll end up with a lot more water vapor than you bargained for when alcohol and water vapor are both evaporating at once.

Connect the refrigerant, which can be tap water, to the dephlegmator. If the tap water is too warm, opt for cold water at 2-3 degrees Celsius. Monitor and maintain the condensate temperature between 85 and 90 degrees Celsius throughout the process.

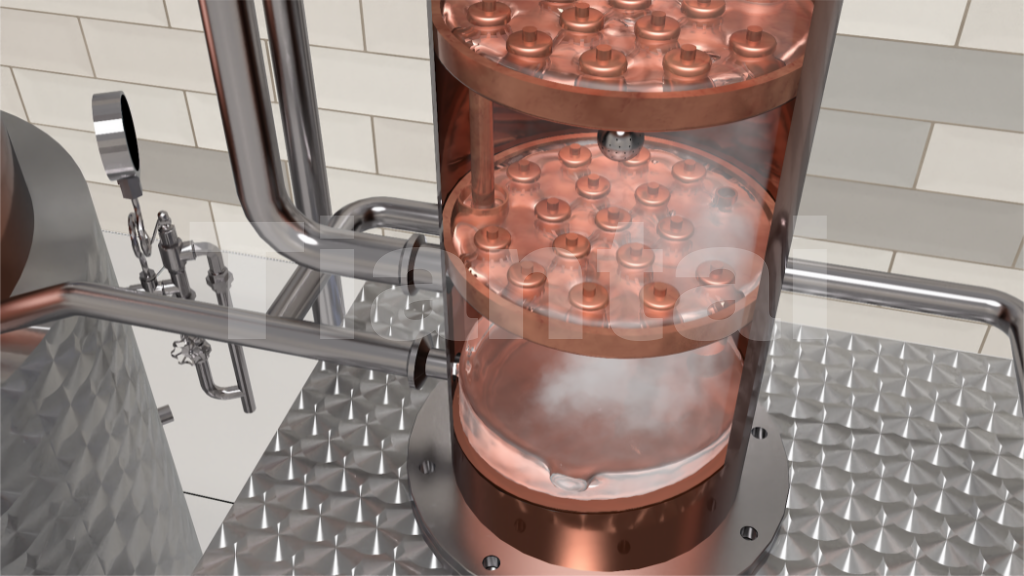

The vapor from the pot enters the column’s bottom through the swan neck, lynn arm, and steam pipe, ascending through each tray from bottom to top. It passes through the water seal on each tray. The condensed water from the dephlegmator forms a water seal on each tray, flowing down layer by layer. As the condensed water seal temperature hovers around 85 degrees Celsius, alcohol vapor continues upward while water vapor remains in the water seal layer.

Control the liquid drip valve of each tray to maintain balanced condensate levels between 5 and 15 mm above the bubble caps.

Adjust the column to achieve a dynamic equilibrium between upward vapor evaporation and downward reflux of cooled condensed water from the dephlegmator refrigerant. Avoid excessive adjustments to preserve this balance.

After passing through the column, alcohol vapor can enter the gin basket, where flavor substances like juniper berries enhance the alcohol’s flavor.

The alcohol vapor with the botanical aroma, goes into the condenser and condenses into a liquid state. Maintain the condensed alcohol outlet temperature at around 20 degrees Celsius for optimal alcohol content measurement and evaporation control, using tap water or cooled water as the refrigerant.

The alcohol vapor, containing water vapor, continues through the condenser. Condensed alcohol vapor flows into the alcohol outlet through an accessory like a parrot’s beak, with three alcohol meters indicating various degrees of alcohol concentration.

During distillation, collect the initial higher-alcohol content, known as the “head,” rich in aldehydes, into the heads storage tank. When the alcohol content reaches 74 degrees Celsius, begin collecting the pure “heart” of the spirits, redirecting it to the heart storage tank. For alcohol content below 62 degrees Celsius, direct the alcohol into the tail storage tank, as it contains more fusel alcohols at this stage. Adjust the switch point based on your recipe.

Collect the heart for further aging and combine the head and tails into the next batch for distillation. Repeat these distillation steps until completion.