The distillation process of whiskey?

What is whiskey?

Whiskey is a spirit distilled from fermented grains (usually barley, corn, wheat, or rye). It is aged in wooden casks, which gives the whiskey its amber color, and must have an alcohol by volume (ABV) of at least 40%. Different types of whiskey are distinguished by their origin, blending process, type of grain used, and aging process. The production of whiskey varies depending on the style of making, country of origin, and other factors, but for the most part, the overall process remains the same. But in general, whiskey is known for its warm, caramelized, spicy, sweet, or toasty flavors.

Whiskey making process

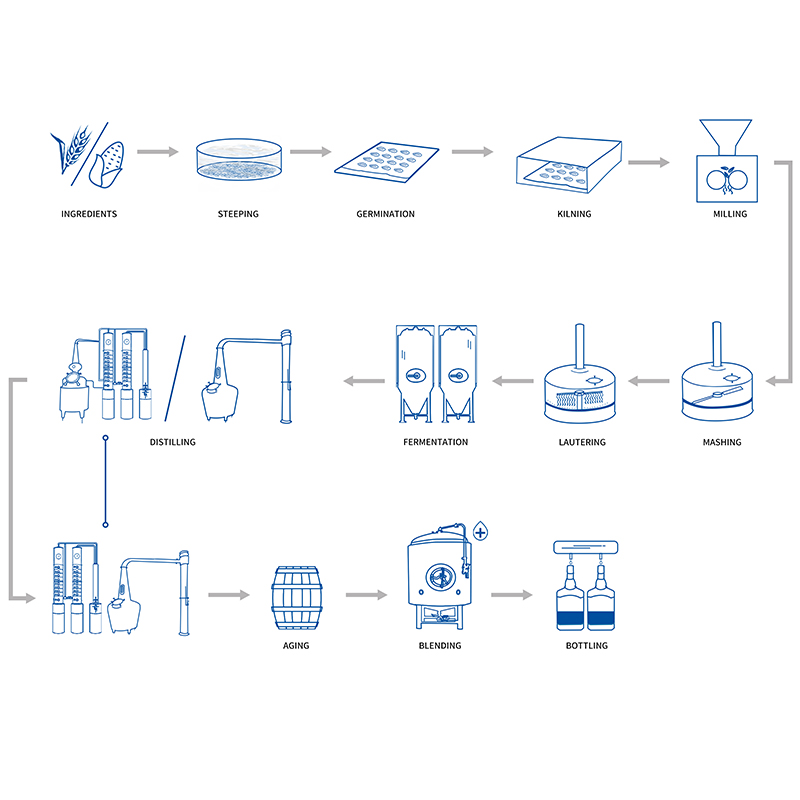

The whiskey production process involves many steps, from malting and mashing, fermentation to distillation, maturation and bottling.

1. Malting

Whiskey is made by extracting sugar from raw grains. Converting barley into malt requires a three-step malting process.

Soaking: Barley grains must be soaked in warm water to increase their moisture content from 14% to about 45%. Germination: After soaking, place the barley on the floor to begin germination. Turning the grains on the floor is essential to avoid excessive heat build-up. Drying: Once the grains have sprouted, the process must be stopped quickly to save the sugar in the grains. This is done by heating the grain in a kiln. If peat is used to heat the kiln, a smoky “peat” whiskey is produced.

2. Mashing

During the mashing stage, the grains are placed in a mash tun along with hot water to remove the sugar from the grains. The mixture is then stirred to form a porridge-like product called mash.

3. Fermentation

Fermentation is the process of converting sugar into alcohol. The mash is placed into a vat called a backwash and yeast is added to begin the fermentation process, which can take 48 to 96 hours. Different types of yeast and fermentation times affect the flavor of whiskey. After fermentation is complete, the still leaves a liquid or wash with an alcohol content of 7-10%.

4. Distillation

The distillation process increases the alcohol content of the liquid and releases both good and bad volatile components. Stills are usually made of copper, which helps remove unwanted flavor and aroma compounds from the spirit. The two most common functionally different types of stills are pot stills and column stills

Pot still

This type of still is commonly used to brew malt whiskey in the United States, Japan, Canada, Ireland, Scotland, and other countries. First, the wash is placed in the still and heated. Since alcohol has a lower boiling point than water, the alcohol turns to vapor and enters the stationary neck and Lane arms and then into the condenser where the alcohol vapor returns to liquid form. After one round in the pot still, the alcohol will be about 20% alcohol by volume. This process can be repeated two or three times, with the final product having an alcohol content of 60-70%.

Column still

Column stills are also called continuous stills, and they are most commonly used to produce rye, bourbon, American whiskey, and grain whiskey from Ireland, Scotland, Japan, Canada, and more.

Because they are a continuous process, they are more efficient than pot stills and eliminate the need to run multiple batches.

Pour the wash liquid into the top of the still and through the perforated plate. At the same time, hot steam rises from the bottom of the still. As the wash and steam interact, any solids are removed and the alcohol vapor begins to rise. Once they hit the plate, the vapors condense, increasing the alcohol content. The final step is to feed the vapor into the main condenser. The process can produce whiskey with an alcohol content of up to 95%, but most distilleries aim for lower alcohol levels.

Another distillation method is a hybrid still using two distillation techniques, which will not be elaborated here.

Mature stage

The aging process is an important part of the whiskey production process. Almost every whiskey is aged in wooden barrels. During the aging process, whiskey barrels are stored in warehouses. During storage, some of the alcohol evaporates, which distillers refer to as the “angel’s share.” As an added bonus, evaporation also makes the warehouse smell wonderful.

Bottling

Once the aging process is complete, the whiskey is ready for bottling and distribution. Some stills filter the whiskey so it doesn’t become cloudy when mixed with water or ice. Ultimately, bottled whiskey must have an alcohol content of 40% or higher. For most large whiskey brands, the bottling process involves the use of dozens to hundreds of barrels from distillery warehouses. When only one barrel is bottled at a time, it is labeled as a single barrel whiskey.