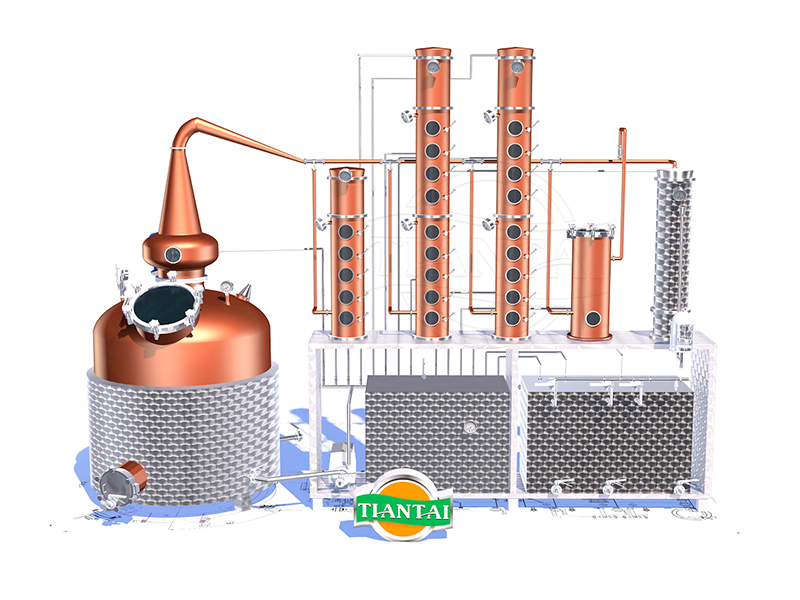

The Key Components of Distillation Equipment

Tiantai designed distillation equipment to transform fermented liquids into refined spirits. Distillation equipment is composed of several key components, each playing a vital role in the distillation process, particularly in the production of spirits like gin, whiskey, and other alcohols. Here’s a breakdown of the characteristics of these parts:

Still Pot:

At the core of the distillation process lies the still pot, a vessel where the initial heating of the fermented liquid (wash) occurs. Typically made from copper or stainless steel, the still pot’s material is crucial for heat conduction and chemical reactions that remove undesirable sulfur compounds, enhancing the spirit’s flavor profile.

Structure: A large, robust metal container (usually made of copper or stainless steel) designed to withstand high temperatures. It often has a rounded or bulbous shape at the base to ensure efficient heat distribution, allowing for an even boiling of the liquid inside.

Helmet:

Positioned atop the still pot, the helmet acts as a transitional chamber for rising vapors.

Structure: A dome-shaped chamber that creates additional space for vapor to expand, facilitating the separation of alcohol from impurities as the vapor rises. The shape and size of the helmet can influence the final flavor of the distilled product.

Swan Neck and Lyne Arm:

Connecting the helmet to the condenser, the swan neck and lyne arm guide the vapors on their journey.

Structure: The swan neck is the elegantly curved section that connects the helmet to the lyne arm, which is typically a horizontal or slightly sloped pipe. The angle of the lyne arm affects reflux—steeper angles encourage condensation, leading to a purer distillate.

Distill Column:

In column stills, the distillation column replaces the swan neck and lyne arm, providing a series of plates or packing materials.Increases the purity of the distillate by facilitating further condensation and vaporization cycles.

Structure: A tall, vertical column packed with plates or packing material. The vapors rise through the column, condensing on the plates and re-vaporizing, which improves alcohol concentration and removes impurities.

Gin Basket:

The gin basket is a unique component for flavor infusion, particularly in gin production.

Structure: A container placed between the still pot and condenser that holds botanicals like juniper, citrus, or spices. As the alcohol vapor passes through, it absorbs the aromatic flavors, resulting in a distinctive spirit.

Condenser:

The condenser cools the alcohol vapors back into liquid form.

Structure: A coiled or tubular component, often surrounded by cooling water, where hot vapor passes through and condenses into liquid. It plays a crucial role in finalizing the distillation process by converting vapor into high-proof alcohol.

Parrot Alcohol Outlet:

The parrot alcohol outlet is an inline device for real-time measurement of alcohol strength.

Structure: A funnel-like apparatus that collects the distillate and channels it into an alcohol meter, providing a continuous reading of the alcohol content as it flows out of the still.

CIP Pipeline:

The Clean-In-Place (CIP) pipeline system facilitates the maintenance of hygiene standards without disassembling equipment.

Structure: A network of pipes connected to various parts of the distillation equipment, allowing cleaning solutions to circulate through the system for thorough sanitation, maintaining hygiene and operational efficiency.

Each of these components works together to ensure an effective and precise distillation process, ultimately shaping the quality and characteristics of the final distilled product.