Understanding Pot Still Definition and Designs

Pot stills, revered for their role in producing classic spirits like malt whiskey, brandy, rum, and schnapps, are the artisan’s tool for creating spirits with unparalleled depth and character. This traditional method of batch distillation is the foundation of many renowned beverages, each reflecting the craft and dedication of its maker. In this exploration, we will delve into the intricate world of pot still distillation, understanding its design, distillation process, and the impact of various factors on the flavor profile of the final spirit.

The Basics of Pot Still Distillation:

Pot still distillation, a form of batch distillation, involves a meticulous process that imparts unique flavors and characteristics to the distilled spirit. The journey begins with the initial distillation, transforming the fermented liquor into a low-alcohol spirit, typically around 25% alcohol by volume for whiskey. The pot still, a simple yet crucial apparatus, plays a pivotal role in this process.

Two Distillations: Crafting Complexity and Quality:

After the first distillation, the still is cleaned, and the once-distilled spirit is reintroduced for a second distillation. This second pass through the pot still elevates the alcohol content to a range of 55-70%, depending on the desired final product. Notably, many single malt Scotch and Japanese whiskeys undergo only two distillations, while Irish whiskey and brandy may go through three or more.

Distilling multiple times results in a purer, higher-alcohol spirit. However, the labor-intensive nature of pot still batch distillation makes it less suitable for repeated distillations, leading to the preference for continuous column stills in such scenarios.

Pot Still Design: A Marriage of Simplicity and Functionality:

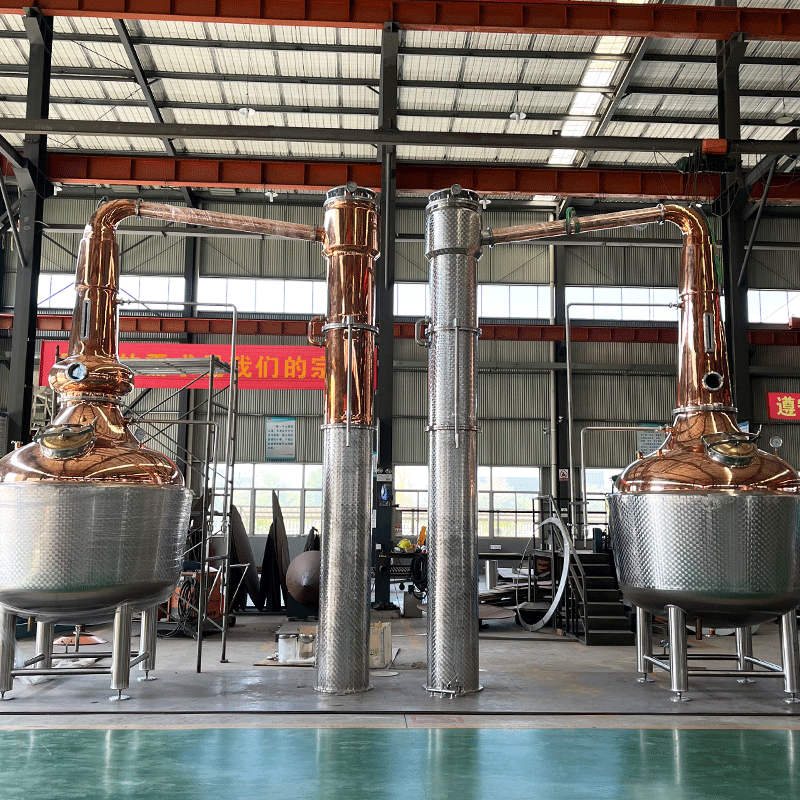

The design of a pot still is elegantly simple, comprising a still and a condenser. The rounded base leads to a long, tapered swan neck or laine arm, connected to the condenser—a spiral tube surrounded by a cooling water jacket. This design facilitates the transformation of beer, wine, or sake into vapor, which then ascends to the swan neck and condenses into liquid form.

The Impact of Shape and Size on Flavor:

The shape and size of the copper pot still are not arbitrary; they significantly influence the flavor of the resulting spirit. The principle is straightforward—the more contact with copper, the lighter and smoother the spirit becomes. Larger and taller stills allow for increased contact, resulting in a lighter spirit, while shorter, smaller stills produce richer, heavier spirits.

Factors Determining Pot Still Quality:

Reflux and distillation rates are pivotal variables in pot still distillation. Reflux, the vapor condensing and falling back into the wash liquor instead of entering the condenser, enhances copper contact, resulting in a lighter alcohol. The shape and angle of the laine arm, as well as the height and shape of the still, influence the amount of reflux.

Distillation speed is another critical factor. Fast distillation means less copper exposure and a heavier, rougher alcohol, while slow distillation produces the opposite effect. The intricacies of these variables showcase the delicate balance distillers must maintain to craft spirits of exceptional quality.

The Crucial Role of the Condenser:

The condenser, a vital component of the pot still, significantly influences the character of the whiskey. The shell and tube still, the most common type of pot still, employs cold water to cool and condense the alcohol vapor, forming droplets that increase contact with the copper shell. This interaction enhances the flavor intensity and complexity of the final product.

Pot still distillation is undeniably laborious, demanding time, money, and effort. It stands less efficient than modern designs, yet the whiskey it produces is of unparalleled quality. The method captures and accentuates the flavor intensity and nuances of the base ingredients, showcasing the artistry and commitment of the distiller.