Distillation Fermentation: The Complete Guide to Yeast Pitching Rates for Maximum Alcohol Yield

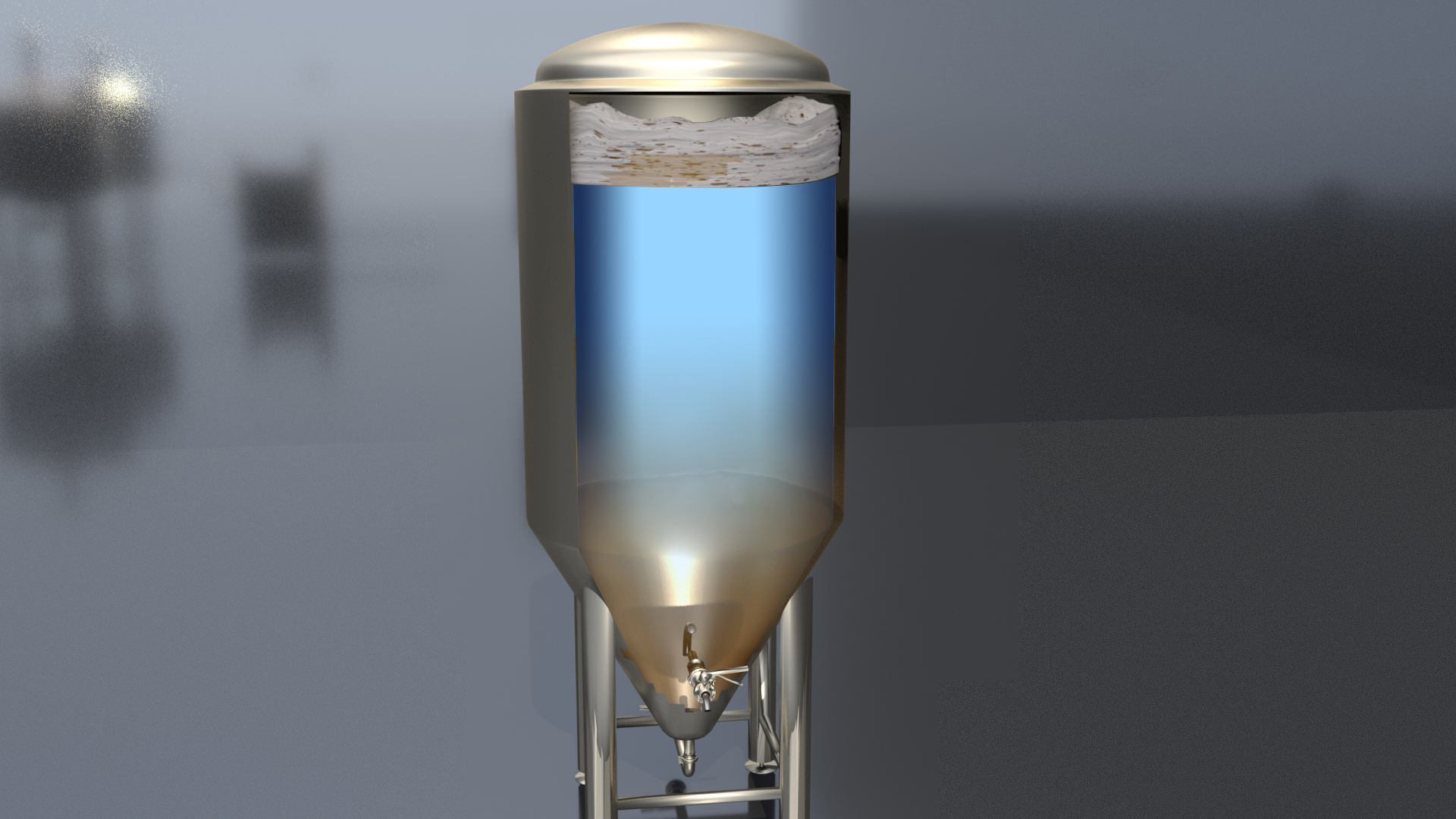

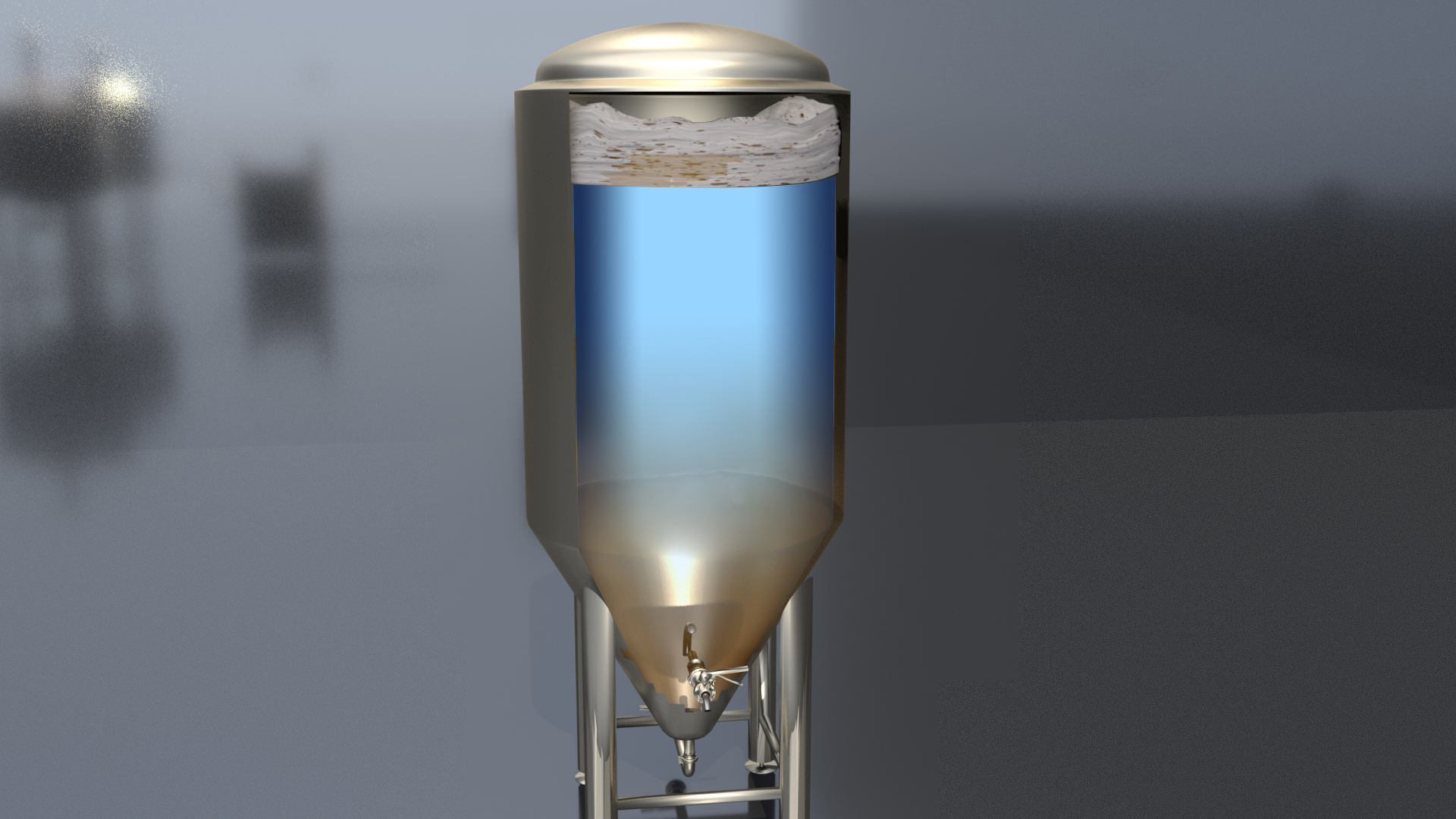

In the journey of spirit production, fermentation is the heart of your alcohol yield and cost-efficiency. A common question we hear is, “How much yeast should I pitch for the best results?” Under-pitching leads to slow, stuck, or contaminated fermentations. Over-pitching is a waste of money and can introduce off-flavors. As your partner in distillation, Tiantai breaks down the science of yeast pitching to help you achieve a rapid, clean, and highly efficient fermentation.

Understanding Pitching Ratios

The pitching rate for distilling fermentations is typically expressed as the weight of pressed yeast as a percentage of the weight of malt and other cereals used (w/w). Industry standards are:

| Distillation Type | Typical Pitching Rate | Rationale |

|---|---|---|

| Malt Distillery | 1.8% | Requires robust yeast activity to handle the complex wort environment and congener development. |

| Grain Distillery | 1.0% | Aims for highly efficient and complete alcohol conversion from a simpler wort. |

Pro Tip: The exact ratio depends on your specific distilling yeast strain and wort gravity.

Practical Calculations: Two Methods for Your Distillery

How do you apply these ratios on the production floor? Here are the two most common methods:

By Grain Weight:

- Standard: A minimum of ~18 kg dry weight of a distilling yeast per tonne of malt.

- With Brewer’s Yeast: If using brewer’s yeast as part of the inoculum, increase the rate to ~22 kg dry weight per tonne.

By Fermentation Volume:

-

Standard: 5 grams of pressed weight of yeast per litre of wort.

-

The Ultimate Goal: Regardless of the calculation method used, the objective is to achieve a pitching rate of approximately 3–4 × 10^7 cells/mL.

The Key Difference in Distilling Fermentations

Unlike brewing, where yeast character is prized, the goal in distilling is singular: maximum theoretical alcohol production.

-

Limited Yeast Growth: Distilling yeast will only divide a few times once pitched. The final yeast concentration is typically around 2×10⁸ cells/mL.

-

The Objective: Minimal growth, rapid onset, and complete attenuation for the highest possible alcohol yield.

An Advanced Technique: The Role of Brewer’s Yeast (Industry Insight)

While uncommon today, traditional practice sometimes involved using brewer’s yeast alongside distilling yeast.

-

How it Works: Pyruvic acid, excreted by the aerobically grown brewer’s yeast, is taken up by the anaerobically grown distilling yeast, thereby raising the wort pH.

-

The Benefit: A higher pH allows amylase enzymes to remain active for longer, continuing to hydrolyse starch into fermentable sugars before a low pH inactivates them, potentially boosting final alcohol yield.

Note: With the demise of local ale breweries in Scotland, sourcing spent brewer’s yeast for Scotch whisky production is now uncommon.

Conclusion

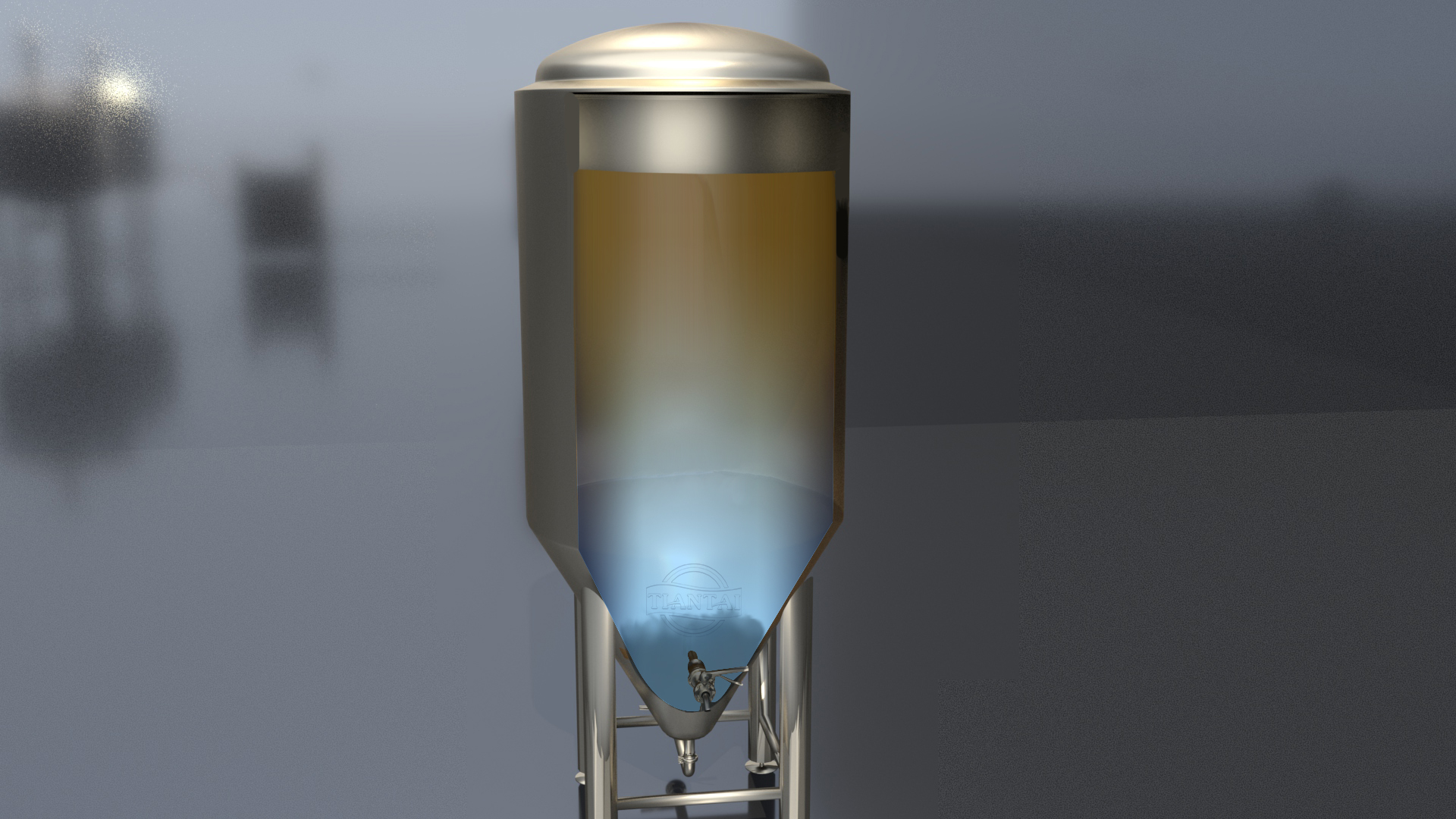

Precise yeast pitching is the foundation of an efficient fermentation. A well-designed distillation system is the final step that transforms the high-quality fermented product into a pure, high-quality spirit.

If you are planning or optimizing your distillation process, Tiantai is your trusted technical partner. We provide not only world-class distillation equipment but also the deep process knowledge to support you from grain to glass.

Contact us today for a free process consultation and a customized equipment quote!