How Pot Stills Influence the Bourbon Whiskey Making Process

If you’re lucky enough to visit a distillery, one of the first things you’ll likely notice are the towering copper stills, which are typically at the heart of the distillation process. While most bourbon whiskey is distilled using modern column stills, some smaller craft distilleries are reviving the traditional pot still method. So, what exactly is a pot still, and how does it influence the flavor and characteristics of bourbon whiskey? This article will explore the role of pot stills in the bourbon whiskey making process and how they affect the final product.

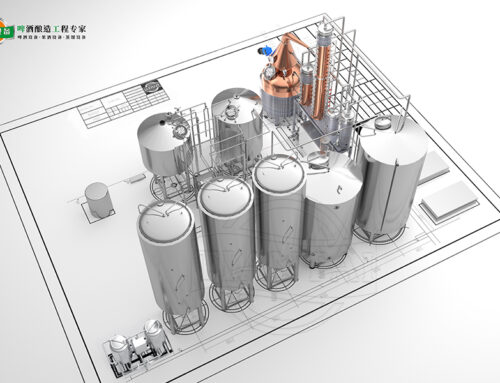

A pot still is essentially a simple yet effective distillation apparatus consisting of three main components: a short, stout base called the still pot; a pipe extending from the top, called the lyne arm; and a condenser, where the alcohol vapor is cooled and condensed back into a liquid. Unlike continuously operating column stills, pot stills distill only small batches of liquid at a time, a characteristic that sets them apart and influences the whiskey’s flavor profile.

The making of bourbon whiskey typically involves three key steps: fermentation, distillation, and aging. After fermentation is complete, the fermented liquid is poured into the still pot of the distillation apparatus. Here’s a brief overview of the process:

Fermentation: Yeast is added to a mixture of corn, barley, rye, and water, producing a low-alcohol liquid called “mash.”

Distillation: The mash is heated in the still pot, causing the alcohol to evaporate. The alcohol vapor rises through the lyne arm to the condenser, where it cools and condenses back into a liquid.

Aging: The distilled liquid, known as “white dog,” is then aged in newly charred oak barrels for several years, during which time it develops its rich amber color and the complex flavors characteristic of bourbon whiskey.

Pot stills are often used by distilleries aiming to produce more complex and full-bodied bourbon whiskeys. The unique distillation method of the pot still is key to achieving this goal. Here are some factors that influence its flavor:

Batch Distillation: Because pot stills use batch distillation, distillers have greater control over the distillation process. They can more precisely monitor and adjust temperature and time, allowing them to extract flavor compounds that might be lost in continuous distillation methods.

Rich and Complex Flavors: Pot stills retain more of the natural flavors from the fermented mash, resulting in whiskies that are typically richer and more complex. The slower distillation process also allows for greater flavor complexity, as different flavor compounds can be separated and purified during distillation.

The Influence of Copper: Pot stills are typically made of copper, which has a unique ability to interact with the distillate. Copper helps remove sulfides and other impurities, resulting in a smoother, cleaner flavor, which is highly valued in premium bourbon whiskey.

While pot stills offer significant advantages in flavor production, they also present some challenges. One major drawback is their intermittent distillation process, meaning that a pot still can only process one batch of liquid at a time. After each batch, the still must be emptied and thoroughly cleaned before it can be used again. This downtime makes pot stills more labor-intensive compared to column stills, which can operate continuously without requiring cleaning after each use.

Given the time and labor costs associated with pot stills, many distilleries opt for column stills. Column stills are more efficient because they allow for continuous distillation, making them more attractive to large-scale bourbon whiskey producers focused on maximizing output and minimizing operating costs.

Despite these challenges, pot stills, particularly in the craft bourbon whiskey sector, are experiencing a resurgence. Smaller distilleries are increasingly using pot stills to differentiate themselves from larger producers and offer more premium, artisanal products. As consumers become more discerning and willing to pay higher prices for high-quality bourbon whiskey, the unique flavors imparted by pot stills are finding a new audience. Some distilleries have even begun using hybrid stills, which combine the best characteristics of both pot stills and column stills. Hybrid stills offer greater flexibility and efficiency while retaining some of the flavor advantages of pot stills.

In the world of bourbon whiskey, the choice of still significantly impacts the final product. Pot stills, while labor-intensive, allow for greater control over the distillation process, resulting in richer, more complex flavors. Although most large bourbon distilleries still use column stills due to their efficiency, the resurgence of pot stills in the craft bourbon whiskey sector highlights the growing consumer demand for high-quality, handcraf