How to Balance Space Utilization and Expansion When Building a Distillery

With the rapid growth of the global spirits market, more and more entrepreneurs and companies are choosing to enter the distilling industry. However, many overlook the importance of space planning when building a distillery. While selecting the right equipment, processes, and recipes is crucial, the layout of the facility is equally important in determining production efficiency, operating costs, and long-term sustainability.

Proper space planning can optimize production workflows, minimize unnecessary downtime, and ensure the business remains flexible and efficient when it comes time to expand. For distillery owners, balancing the use of limited space with the need for future expansion is a critical consideration.

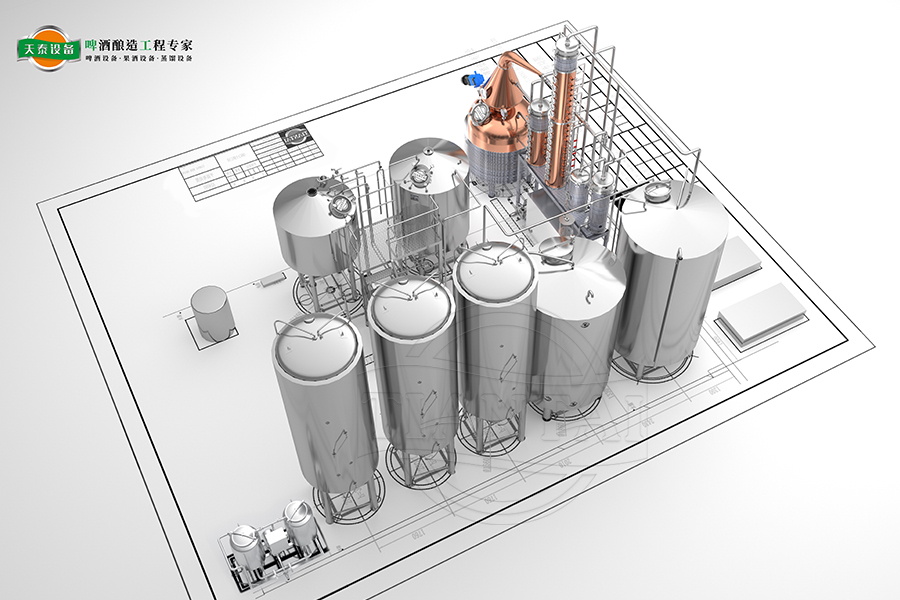

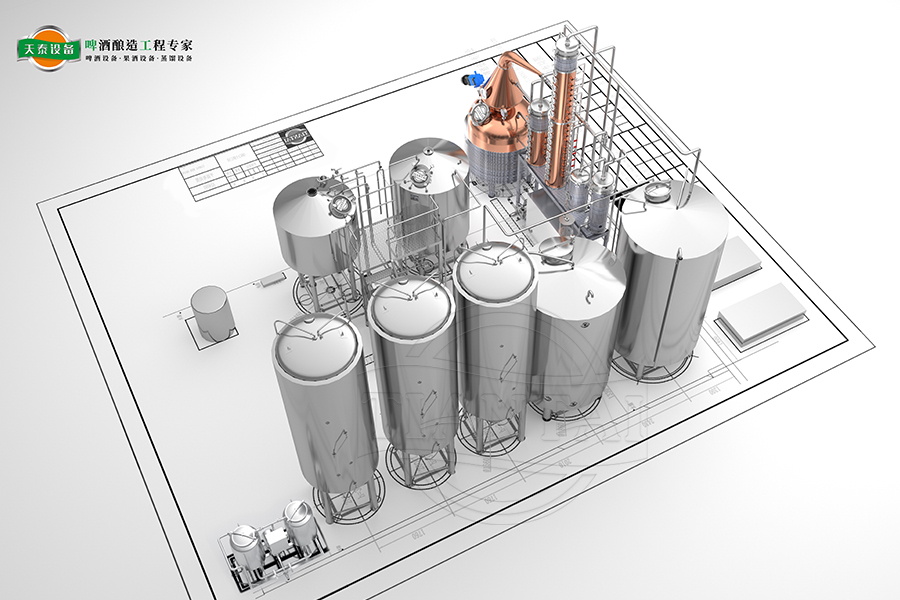

The core of a distillery is its production process, which often includes several stages, such as raw material preparation, fermentation, distillation, storage, and packaging. A well-designed layout ensures smooth transitions between these stages, minimizes safety risks, and boosts overall efficiency. More importantly, the facility’s space should not only meet current production needs but also provide the flexibility for future expansion and equipment upgrades.

Many startup distilleries focus too heavily on immediate production demands and overlook potential market growth and equipment updates. This short-sighted approach can lead to costly renovations later if space becomes insufficient. In other words, today’s space planning has a direct impact on future operational costs, expansion speed, and production flexibility.

An efficient distillery typically includes the following core areas:

Production Area

The production area is the heart of the distillery, where key processes such as raw material handling, distillation, cooling, and storage take place. When planning this area, it’s important to consider equipment placement, operator workspace, and the flow of materials. For a small to medium-sized distillery, the production area typically ranges from 100 to 300 square meters, and every inch of space should be maximized.

Fermentation Area

Although the distillation process occurs in specialized equipment, the fermentation area is also crucial. Fermentation is an essential step in the brewing process, and it often requires temperature and humidity control. Therefore, the fermentation area should be spacious enough to accommodate large fermentation tanks and allow for flexible configurations to adjust or expand as needed.

Storage Area

The storage area is typically divided into two main sections: raw material storage and finished goods storage. Raw material storage is where ingredients like grains, sugars, and spices are kept, while finished goods storage holds the distilled spirits and packaged bottles. As production scales up, the need for more storage will increase. Thus, it’s essential to allocate additional space in the design to accommodate future growth.

Packaging and Bottling Area

The packaging and bottling area’s design will often evolve as market demands and production volumes increase. A well-designed packaging area should support the installation of automated equipment to reduce manual labor and increase efficiency. Additionally, hygiene standards in this area must be high, with clear and easy-to-clean pathways and equipment layouts.

Laboratory and Quality Control Area

Quality control is crucial for a distillery’s operations. The laboratory should be equipped with efficient testing equipment and ventilation systems, and it must be kept separate from the high temperatures, humidity, and other conditions that could impact testing results. The independence and privacy of the laboratory and quality control area should be prioritized.

Employee Facilities and Offices

Even a small distillery requires office space for daily operations, finance, sales, and administrative tasks. Providing comfortable employee lounges, changing rooms, and restrooms not only boosts employee satisfaction but also ensures safety and health standards during production.

Customer Experience Area

If the distillery plans to host visitors or conduct tastings, a customer experience or tasting area is essential. This area must be both comfortable and attractive while maintaining clear safety separation from the production zones to avoid disrupting the manufacturing process.

Several factors play a crucial role in the design of a distillery:

Production Capacity and Equipment Needs: Production capacity will dictate the size and layout of key equipment, including distillation units, fermentation tanks, and storage vessels.

Process Complexity: Distilling processes vary by type of spirit, and some distilleries may need additional storage for spices or more advanced cooling systems. These specific requirements should be considered during the early planning stages.

Site Conditions: The facility’s ceiling height, floor load capacity, aisle width, drainage, and ventilation systems are all critical to the installation of equipment and future expansion.

Workflow Optimization: A well-planned layout reduces the time operators spend moving between areas and minimizes the risk of cross-contamination. For example, material flow paths should be clear, and distinct boundaries should separate production, cleaning, and packaging zones.

Future Expansion: Even a startup distillery should consider future expansion. During the design phase, reserve 10%-20% of the space for adding equipment or increasing production capacity.

Safety and Utilities: Proper infrastructure, including fire exits, electrical systems, steam and cooling systems, wastewater treatment, and general utilities, must be in place to ensure safe and sustainable operations.

Balancing Space Utilization and Future Expansion

Modular Design: Adopting a modular design allows different production areas (e.g., distillation, fermentation, packaging) to be adjusted or expanded as needed. Modular systems not only save on initial investments but also make it easier to scale up based on future demands.

Detailed Budgeting and Planning: When working within a tight budget, space planning should be highly detailed to avoid waste, while ensuring that areas for future expansion are still functional and accessible.

Pre-set Interfaces for Future Equipment: During the construction phase, make sure to design spaces with the potential for additional equipment. By planning for future expansion, the distillery can avoid costly disruptions caused by incompatible equipment later on.

Multi-Functional Space Design: Certain areas, such as storage or packaging zones, can be designed to serve multiple purposes. This allows the space to evolve as production demands increase without requiring major redesigns.

When building a distillery, careful space planning not only improves current production efficiency but also provides flexibility for future expansion. By balancing space utilization with the ability to scale, distillery owners can ensure that their operations remain efficient and responsive to market growth. Investing in thoughtful, well-designed facility layouts is the foundation for the long-term success of any distillery.