How to plan and design your distillery?

When planning to set up a distillery, one of the initial questions is often, “How big should the still be?” While this is a critical factor, the scope of your equipment choices hinges on a much broader set of considerations. Before selecting equipment, it’s essential to have a clear vision of what you intend to produce, at what volume, and for which markets. This begins with developing a comprehensive financial model and a strategic business plan. With these foundations, you can design a distillery system that not only fulfills your current needs but is scalable to support future growth.

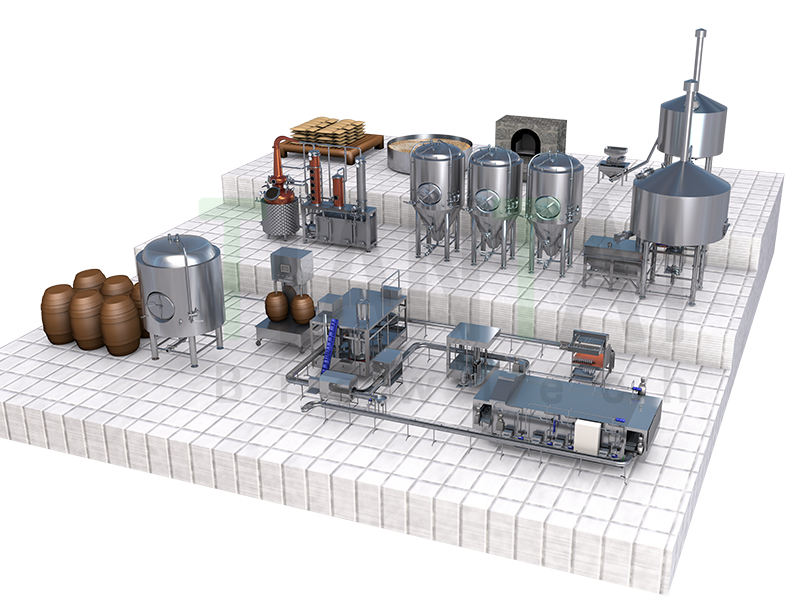

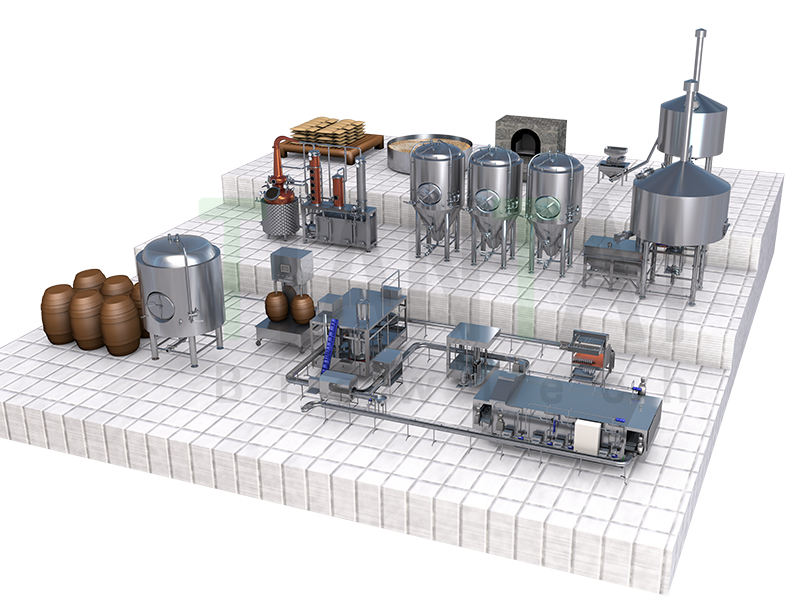

A distillery is more than just the still. The heart of the operation might be the distillation units, but efficient production requires a host of other essential components working seamlessly together. In addition to milling, cooking, fermenting, and distilling equipment, it’s important to design a system that includes robust support utilities. These systems—cooling, heating, steam generation, and filtration—ensure that your distillery operates efficiently and consistently.

When designing your distillery, flexibility is key. Whether you’re producing whiskey, vodka, or other spirits, your equipment layout and system design should accommodate both your immediate production goals and long-term growth. This includes thinking about space utilization, equipment capacity, and the ability to scale up production as demand increases. Proper planning will prevent bottlenecks in your process and allow for smooth expansion as your distillery grows.

Before committing to specific equipment, consider several critical questions that will shape the design and functionality of your distillery. These questions will help ensure that you select the right equipment for your needs and avoid costly mistakes down the road.

1. What Spirits Will You Produce?

The type of spirits you plan to produce will dictate much of your equipment choice. For instance, producing whiskey generally requires a simple pot still with minimal trays, while vodka production demands higher purity and often requires a multi-column system with up to 40 trays in each column to achieve the desired level of purity.

Additionally, if you plan to produce gin, it’s often recommended to have a separate still dedicated to botanical infusions. This prevents cross-contamination of flavors that could affect the quality of other spirits in your production line. Depending on your product portfolio, you may need multiple specialized stills to ensure efficient and high-quality production across different spirit types.

2. What Are Your Projected Production Volumes?

Understanding your production volume is essential for sizing your equipment. This includes not only your current production needs but also projected volumes for the next 5 to 10 years. By planning for future growth, you can select equipment that meets your initial needs but also has the capacity to handle increased output without major modifications.

At Tiantai, we work closely with distillery clients to strategically size equipment to hit desired production volumes on a single work shift. This approach not only maximizes production efficiency but also helps keep labor costs manageable—a critical consideration given that labor is one of the largest cost drivers in distillery operations.

3. How Will Your Layout Support Growth?

Another key factor is the physical layout of your distillery. Proper space planning will allow for efficient movement of raw materials, intermediate products, and finished goods. It will also accommodate future equipment expansions without the need for major renovations. Considerations like ceiling height (for tall distillation columns), access to utilities (such as steam and cooling), and the ability to add more fermentation tanks should all factor into your initial design.

At Tiantai, we specialize in crafting distillery systems tailored to meet the unique needs of each client. Our expertise ensures that your equipment will be perfectly suited to your production goals, both now and as your business expands.