The Ultimate Guide to Distillery Cleaning & Hygiene Protocols for Premium Whisky Production

Maintaining strict hygiene throughout whisky production is essential for quality, consistency, and safety. Even minor contamination can introduce off flavours, spoilage organisms, or regulatory headaches. Every stage – from grain intake to bottling and storage – must be kept clean and sanitary. High-quality distillery cleaning equipment (stainless tanks, fermenters, spray heads, CIP systems, etc.) is crucial to meet these challenges efficiently. Tiantai reviews hazards at each production stage and recommends cleaning methods (such as caustic wash, acid rinse, foam cleaning, and steam sanitation) to maintain whisky production hygiene and equipment longevity.

Grain Receiving and Milling: Preventing Contamination

Raw grain can carry foreign matter (stones, metal), insect pests, or mould that spoil whisky flavour and fermentation. Poor grain sanitation can even introduce off-odours that carry through to the spirit. Best practices include:

- Inspection and Screening: Use magnets and grain cleaners at intake to remove metal and debris. Discard moldy or musty grain to avoid taint.

- Clean Conveyors and Bins: Grain handling equipment (augers, conveyors, storage silos) should be emptied and cleaned regularly. High-quality grain bins are designed to avoid crevices where material lodges.

- Environmental Controls: Keep receiving areas dry and well-ventilated. Remove dust and chaff to prevent microbial growth. Maintain pest control measures around grain stores.

Periodically wash out intake chutes and grain grinders with compressed air or water to clear residual flour and debris. Although rigorous chemical sanitization isn’t used on raw grain, regular mechanical cleaning of grain floors and milling equipment is a distillery maintenance best practice. Stainless steel conveyors and sealed hoppers can simplify cleaning and help prevent hidden spoilage hotspots.

Mashing and Wort Preparation: Removing Residues

After milling, the grain meal is cooked and mashed. The mash tun, cooker, and whirlpool see heavy organic soils (starch, proteins) and can develop hard deposits. Key steps:

- Immediate Rinse: Flush mash tuns, cookers, and hoses with hot water after each batch. This removes soluble sugars and grain solids before they dry.

- Caustic Cleaning: Use a caustic alkaline wash (sodium hydroxide) in a clean-in-place (CIP) system to dissolve stubborn organic soils and proteins. Modern CIP solutions often include surfactants and chelators to enhance action and reduce the need for harsh chemicals.

- Acid Rinse: Follow caustic wash with an acid rinse (phosphoric or nitric acid) to remove mineral scale, especially on steam-jacketed heaters. Acid cleaners also free metallic ions and brewer’s stone (calcium oxalate).

- Foam Cleaning: For vessel exteriors and encrusted areas, foam cleaning can be effective. Foaming agents cling to the surface, breaking down soils without high-pressure spray. This is useful for large mash vessels or heating coils not reached by CIP.

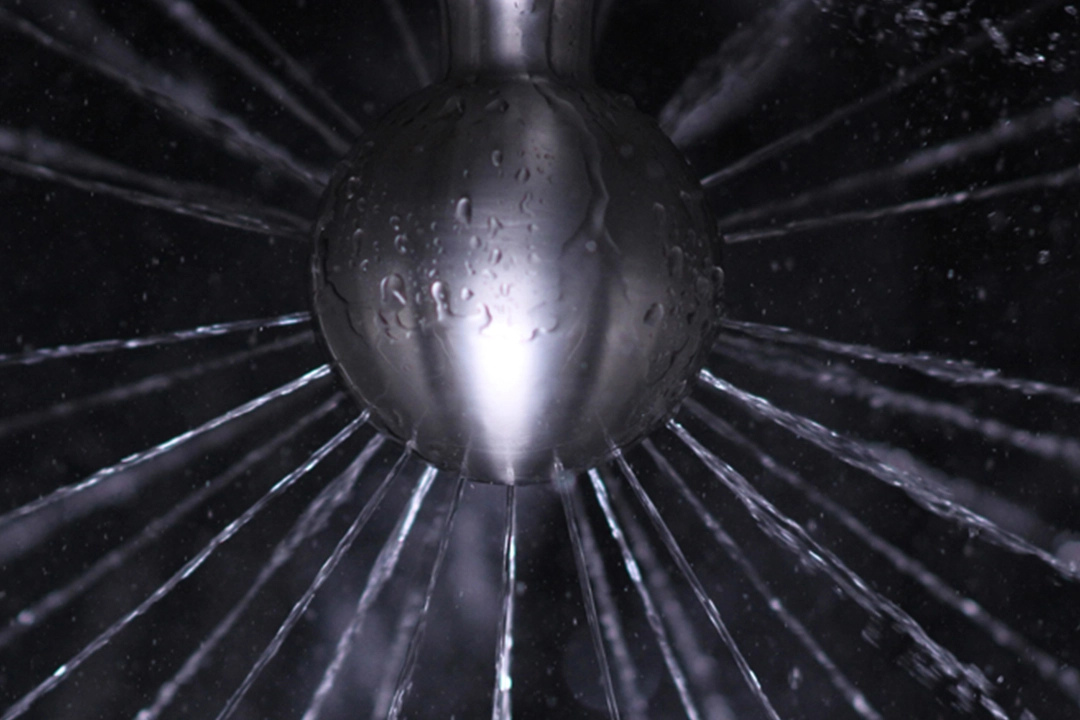

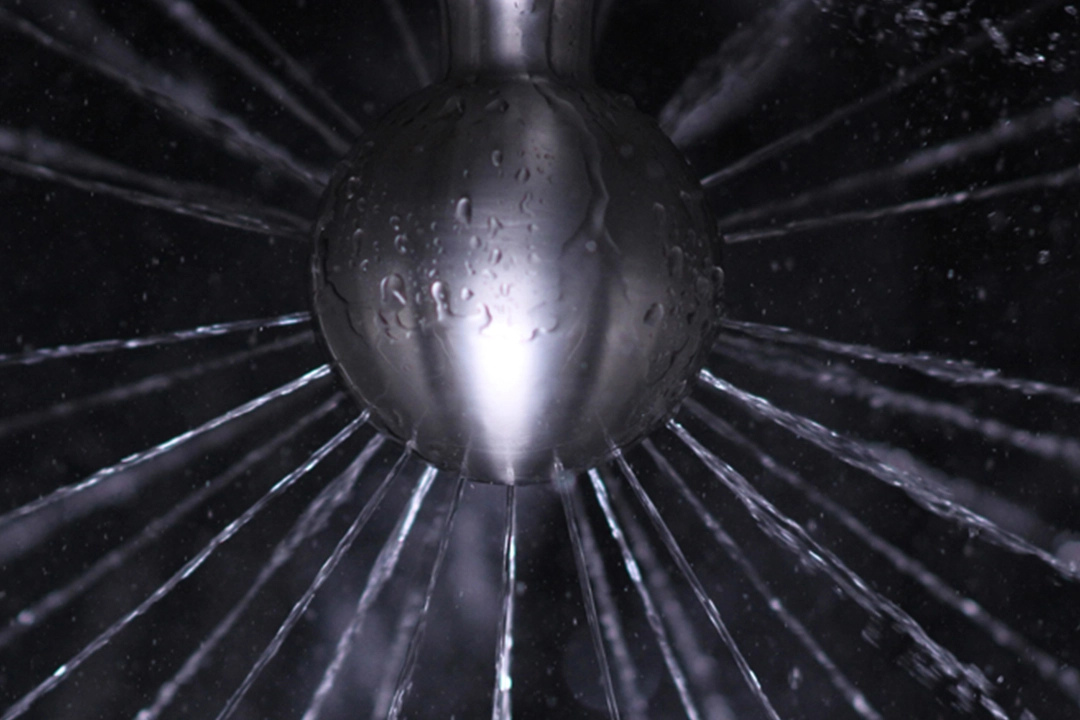

- Tiantai Design: High-quality mash tuns and kettles include removable or CIP spray heads that reach all surfaces. Properly placed sprayballs ensure the entire tank surface is reached, covering any shadowed areas. Smooth interior welds and drain valves prevent food soils from hiding in crevices.

In summary, rigorous CIP with caustic and acid cycles (often automated) keeps mash vessels sanitary. Any charred or baked-on material inside direct-fired kettles may require periodic hand cleaning or concentrated alkaline soaks, highlighting the value of advanced steam-jacketed or electric-heated tanks that minimize scorching.

Fermentation: Sanitizing Vessels and Lines

Fermentation is particularly sensitive to microbial contamination. Unwanted bacteria (e.g., lactic, acetic, butyric) or wild yeasts can consume sugars or create off flavours (“pepper whiskey”), reducing yield and spoilage risk. To protect fermentation:

- Thorough Cleaning and Sanitizing: Wash fermenters, yeast tanks, and all transfer lines with hot water to flush mash and yeast out. Then apply chemical sanitizers (e.g., peracetic acid, hydrogen peroxide, or steam) to kill microbes. Lines carrying yeast or mash must be washed with hot water and then subjected to steaming when not in use.

- Caustic and Acid CIP: Periodically run caustic CIP through fermenters as above, removing protein and yeast residues. An acid rinse eliminates any mineral buildup on coils or chillers. These steps prevent nutrient film formation that bacteria could colonize.

- Enzymatic Cleaners: Enzyme-based cleaners (protease, amylase) can be used on fermentation equipment to break down sugars, starches, and proteins in one step. They are gentle on stainless surfaces and eco-friendly.

- Tiantai Design: High-quality stainless fermenters with sealed doors, CIP spray heads, and tight gaskets minimize contamination risk. Foam-control spray balls or detachable paddles allow cleaning even under bungs and agitators.

- Preventing Flavour Carryover: Strict separation of yeast strains by cleaning prevents cross-contamination. Even tiny residues of yeast, mash, or cleaning agents left in fermenters can carry flavor or spoilage from one batch to the next. Documenting cleaning cycles (as required by regulators) ensures consistency.

Adhering to a daily cleaning schedule is critical. Regular inspection of fermenter exteriors (for mold or grime) and cooling coils (for biofilm) is also recommended.

Distillation: Ensuring Purity of Spirits

During distillation, volatile compounds are separated – so any contaminant in stills or condensers can taint the spirit. Hazards include caramelized solids in the still, water-scaling in boilers, or residues in condensers. Cleaning focus here includes:

- Still and Boiler Cleaning: After a run, flush out still pots and columns with hot water. Use CIP circulation or pressure wash to remove trub and spent lees. For heavy fouling (burnt sugars), recirculate a hot caustic solution. If stainless jackets or coils have scale, an acid clean (nitric or sulfamic acid) will dissolve deposits.

- Condenser and Chiller Maintenance: Condensers and plate heat exchangers should be cleaned regularly. Scale and biofilm can reduce efficiency and trap bacteria. Many distillers use CIP or COP (clean-out-of-place) cleaning for heat exchangers, circulating caustic and acid solutions through alternate ports.

- Steam Sanitization: Before and after runs, steam the still via a steam coil or injector. This pasturizes interior surfaces and lines. Steam is also used between products (e.g., gin vs. vodka) to eliminate flavor carryover.

- Tiantai Design: Modular stills (column, pot, and hybrid) made of high-grade copper with hygiene welds are easier to clean. For example, reflux columns often have removable plates or sight glasses that facilitate inspection and cleaning. Built-in CIP spray balls in pot still domes can reduce manual entry for cleaning.

- Waste Handling: Proper disposal of spent wash/wastewater prevents fouling sumps and drains. Routinely scrub floors under stills and freezers to prevent sticky residues that attract microbes.

In every case, a combination of caustic and acidic cleaning is needed. Residues from fermentation and distillation can build up. Caustic cleaners are highly effective at breaking down these tough residues, helping maintain efficiency and prevent off-flavours in spirits. High-quality distillation equipment with accessible ports and CIP connections makes this upkeep far easier and faster.

Proofing and Blending: Maintaining Quality

After distillation, new-make spirit is often too high-proof for bottling. It’s diluted (“proofed”) with water or blended with other spirits. Cleanliness here ensures water purity and consistent flavour:

- Water Filtration and Sanitization: Since water makes up most of the final product, use filtered or UV-treated water for proofing. Maintain and clean dilution tanks and pipelines frequently. If static tanks are used, empty and rinse them after filling.

- Blend Tanks: When blending vats hold multiple spirits, they must be spotless to avoid cross-tasting. CIP systems and sprayballs in blend tanks ensure thorough rinsing. Clean and sanitize any pumps or transfer lines used for adding flavourings or caramel coloring.

- Calibration and Instruments: Clean hydrometers, density meters, and pH probes before each use. Even small residues on instruments can skew readings.

- Regulatory Compliance: Proofing often has tax/labelling implications, so precise cleaning prevents contamination that could alter measured ABV. Maintaining clean gauge ports and proofing tanks supports accurate compliance reporting.

Because proofing changes the spirit profile, any bacterial or particulate contamination can dull flavors. A rinse with a mild sanitizer (peracetic acid or citric acid) followed by water flush keeps tanks hygienic without affecting taste.

Bottling and Packaging Hygiene

The final production stage is particularly unforgiving: contaminated bottles or caps ruin a batch. Key practices include:

- Equipment CIP: Bottle fillers, capper heads, and conveyors should be cleaned and sanitized nightly and at each start-up. Use CIP sprayballs or disassemble and wash small parts (valves, nozzles) in a COP washer.

- Bottle Cleaning: Many distilleries pre-rinse bottles with CO₂ or water to remove dust. Some use steam or chemical spray on empty bottles (especially for re-used bottles) before filling.

- Sanitizer Rinsing: PAA or peroxyacetic acid is popular for no-rinse sanitizing in bottling lines because it kills microbes without leaving harmful residues. This ensures final products are sterile when filled.

- Clean Utilities: Use sanitized water for all cleaning. If reused, filter or replace water frequently to avoid biofilms. Compressed air for bottle blowing should be oil- and bacteria-free.

- Environmental Controls: Keep packaging areas clean and dust-free. Frequent sweeping, wiping of surfaces, and air filtration minimize contamination risks. Floor drains near fillers should be cleaned to prevent stagnant water.

- Validation: Many distilleries conduct ATP tests or swabs on conveyors and filler surfaces to verify cleanliness. Document cleaning schedules and results as part of distillery maintenance best practices.

Bottling lines and associated equipment should be cleaned and sanitized at shutdown and again at start-up. Neglecting this can allow spoilage yeast/bacteria to slip into the final product, causing refermentation or off-flavours. Investing in a Tiantai automated CIP cart or foam cleaning station for the bottling line can pay off by saving labor and improving consistency.

Warehouse and Cask Storage Hygiene

Aging whiskey in barrels takes place over years – but warehouse hygiene still matters for safety and quality:

- Barrel Handling: Ensure barrels are intact and not leaking. Wipe off any drips or spills from proofing. If barrels are wet on the outside, sanitize with steam to prevent mold. Keep newly emptied barrels clean if they will be reused or sold.

- Environmental Monitoring: Maintain appropriate temperature and humidity. High humidity (>55%) can promote mold on barrel exteriors and support pests. Periodically inspect rick walls and floors for mold or standing water.

- Pest Control: Protect warehouses against rodents and insects that can contaminate barrels or packaging materials.

- General Cleanliness: Keep floors swept and free of grain/mead, and use industrial cleaning systems (power washers, scrubbers) on concrete or wooden floors to remove residue. Dust barrels and beams regularly; clean airflow vents and fans.

- Barrel Cleaning (if needed): Occasionally, cellars use steam or fungicide fogging to control mold in extreme cases. However, chemicals should not contact barrels directly, as they can affect flavor.

Well-maintained warehouse conditions prevent dangerous accidents (slippery floors, collapsing stack hazards) and ensure compliance with safety regulations. Using instruments like hygrometers and recorders can help monitor conditions continuously. High-quality storage racks and forklift-accessible layouts also facilitate easier cleaning and inspections.

Investing in robust distillery cleaning equipment (durable pumps, valves, coated floor drains, splash guards) and designing plants for hygiene (sloped floors, rounded corners) reduces cleaning labor and increases safety. Ultimately, well-maintained equipment runs longer and produces more consistent whisky – proof that cleanliness and quality go hand in hand.

Conclusion: Cleanliness is the foundation of premium whisky. By following strict hygiene protocols – from grain intake to the aging warehouse – distillers avoid spoilage, preserve flavor clarity, and meet regulatory standards. Using specialized cleaning methods (caustic washes, acid rinses, foam and steam) and high-quality equipment (CIP systems, stainless tanks, sanitary spray heads) allows efficient, thorough sanitation. In turn, this protects your product’s reputation and your bottom line. In the end, investing in a clean distillery is investing in great whisky.

By choosing Tiantai, you’re investing in equipment that not only meets but exceeds cleaning standards, helping you produce award-winning whiskies. Visit our site today to explore our full range of distillery and more, optimized for your success in the spirits industry.