The Wash Still Operation: Precision, Efficiency, and Modern Solutions

Distillation is at the heart of whisky and spirit production, and the wash still plays a crucial role in defining both efficiency and final spirit quality. While the process is rooted in centuries of tradition, modern distilleries now have access to advanced equipment and techniques that improve energy efficiency, ensure safety, and deliver consistent results.

Preparing the Wash Still

The distillation journey begins with fermented wash, typically at an original gravity (OG) of 1050–1060° (12.5–15° Plato). Before charging the still, the wash is often preheated using energy recovery techniques—for example, by heat-exchanging with hot liquor from a previous distillation. This not only saves fuel but also reduces the risk of fouling or charring inside the still.

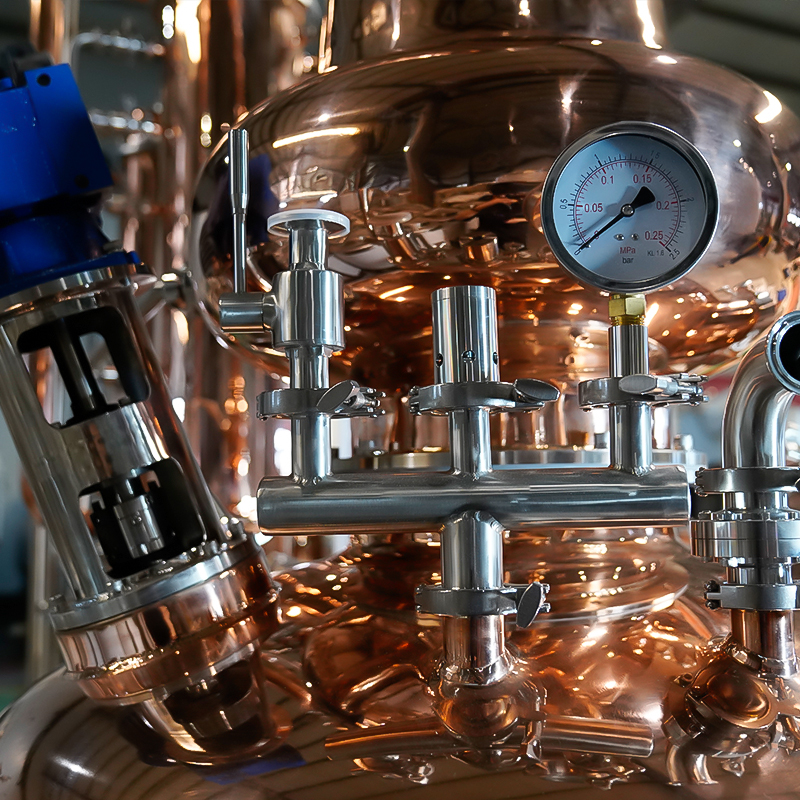

The still is then charged to about two-thirds of its capacity. Care must be taken during this stage: discharge valves, charging valves, and anticollapse valves must all be checked and properly set to avoid accidents. Tiantai supplies stills and automation systems with integrated valve interlocking and PLC control, ensuring a safe and reliable charging sequence.

Managing the Distillation

Once charged, the heat can be applied. At first, a gentle rise is required to prevent boil-over and “foul distillation.” As the wash begins to froth, operators rely on sight glasses and monitoring systems to judge when to increase heat safely. When the frothing subsides, heat can be raised to maintain a steady flow of low wines.

Distillation is typically followed by hydrometry, with collection continuing until the spirit measures around 1% ABV. This balance ensures efficient recovery without wasting energy. A typical cycle lasts 5–8 hours, aligning with fermentation and mashing schedules.

With our modern still designs, uniform heating and precision temperature control make this stage both safer and more efficient, helping distilleries maintain quality while reducing fuel costs.

Safety and Cleaning

One of the biggest risks in wash still operation is pressure imbalance. At the end of distillation, opening the air valve is vital to prevent still collapse, especially if the anticollapse valve malfunctions. Our stills are designed with redundant safety systems and durable construction, giving operators peace of mind.

Cleaning is another key aspect. Overheating or poor wash preparation can lead to charring on heating surfaces, which reduces heat transfer efficiency. Traditional caustic cleaning is effective, but manual scrubbing is both time-consuming and hazardous. Modern CIP (Cleaning-in-Place) systems, which we integrate into our equipment, allow distilleries to clean thoroughly, recycle cleaning agents, and reduce operator exposure to chemicals. This is not only safer but also more sustainable.

Final Thoughts

For distilleries aiming to combine traditional craftsmanship with modern efficiency, choosing the right equipment partner is essential. As a leading distillation equipment manufacturer, we provide custom-designed stills, automation systems, and CIP solutions that not only preserve tradition but also embrace innovation—helping distilleries produce exceptional spirits safely, consistently, and sustainably.