The Distillation Process of Brandy

Brandy is a unique distilled spirit made entirely from fermented fruit juice, fruit puree, or fruit wine. Unlike grain-based spirits, brandy can only be made from fruit, with grapes being the most common raw material. Apples, peaches, pears, and other fruits are also frequently used to produce distinctive fruit-flavored brandies around the world.

Although the production processes of brandy and wine are similar, many people confuse the two. Both start with the fermentation of fruit into wine, but the essential difference lies in the distillation process. Brandy is essentially wine that has been distilled into a spirit, resulting in higher alcohol content, richer flavor, and more complex aromas.

So, how is brandy made? Below is a detailed explanation of each stage of the brandy production process.

1. Fermentation

Fermentation is the first and most fundamental step in making brandy. The quality of the final spirit is largely dependent on the type of fruit used and the fermentation process.

Fresh fruit is first pressed into juice or puree. Yeast is then added to the fruit mixture, initiating fermentation. During this process, the natural sugars in the fruit are converted into alcohol. The result is a fruit wine with relatively low alcohol content, which serves as the base for distillation.

Various fruits can be used for fermentation to produce brandy. While grape brandy is the most common, apple brandy, peach brandy, and other fruit brandies offer unique flavor profiles that reflect the characteristics of the fruit used.

2. Distillation

After fermentation is complete, the fruit wine needs to be distilled. This is the key step that transforms the wine into brandy by concentrating the alcohol and enhancing the flavors.

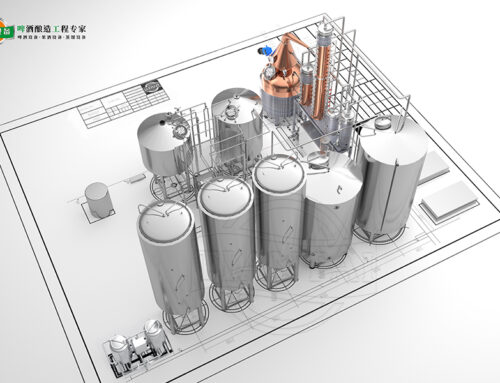

Distillation can be carried out using two main types of equipment:

Pot Stills: These traditional distillation vessels are commonly used in artisanal and premium brandy production. They operate in batches and typically produce brandy with a rich, complex, and layered flavor profile.

Column Stills: In contrast, column stills are more efficient and suitable for large-scale production. They allow continuous distillation, typically producing a lighter and purer-tasting brandy.

The choice between pot stills and column stills has a significant impact on the final flavor characteristics of the brandy.

3. Aging

After distillation, brandy is usually aged in oak barrels. Aging plays a crucial role in developing the spirit’s aroma, flavor, and color.

During maturation, the brandy interacts with the oak, absorbing compounds that impart notes of vanilla, caramel, spices, and toasted wood. The color of the brandy also deepens from clear to a warm amber hue. The length of aging depends on regional regulations and the desired style; generally, longer aging results in a smoother, more complex brandy.

4. Blending

In larger distilleries, blending is a vital part of the brandy production process. Brandy from different barrels, vintages, or batches is carefully blended to achieve a balanced and harmonious flavor profile.

Blending helps improve the stability of the spirit, ensuring consistent quality and flavor in every bottle. It allows consumers to enjoy the same taste and quality in every purchase.

5. Bottling

The final stage of brandy production is bottling. Before bottling, the brandy may be filtered to improve clarity and adjusted to the desired alcohol content.

Once bottled, the brandy is labeled and distributed to various markets for enjoyment.

If you have any questions about brandy production or distillation equipment, feel free to contact Tiantai, and we will be happy to provide professional assistance and technical support.